DIN2391 High Pressure hydraulic Galvanized Steel Tubing

Product Detail

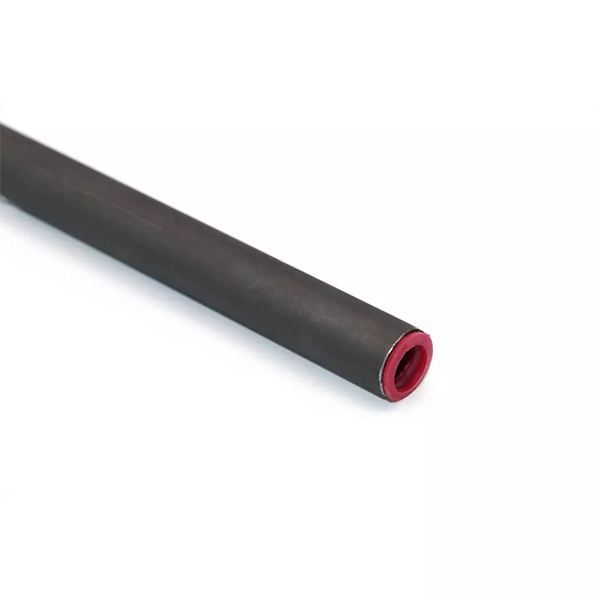

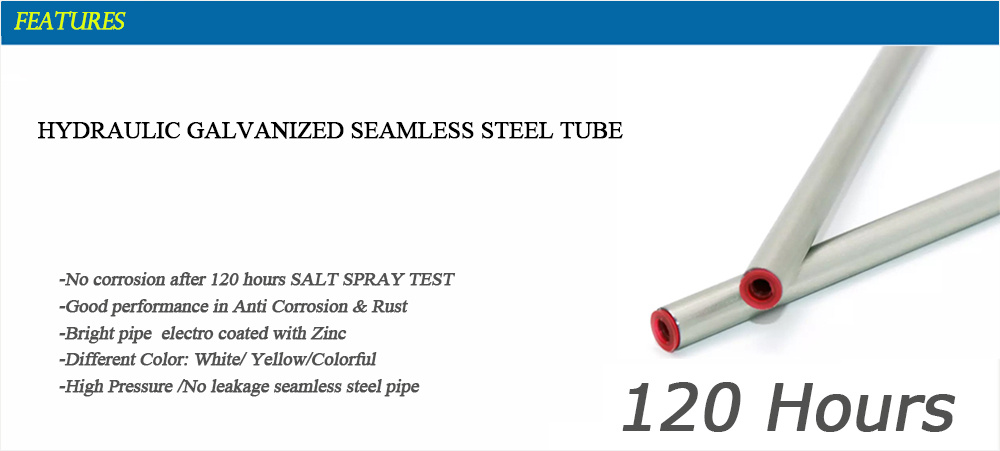

DIN2391 High Pressure hydraulic Galvanized Steel Tubing yog tsim los ntawm DIN 2391-C.Nws yog dav siv nyob rau hauv hydraulic systems, tshuab cuab yeej, tsheb, nkoj, kev tsim kho machinery thiab tsheb.Lub Hydraulic galvanized seamless steel raj nrog high precision muaj ntau qhov zoo: Tsis muaj corrosion tom qab 120 teev SALT SPRAY TEST;Kev ua tau zoo hauv Anti Corrosion & xeb;Bright yeeb nkab hluav taws xob coated nrog Zinc;Xim txawv: Dawb / Daj / Xim Xim;High Pressure / Tsis xau seamless steel yeeb nkab.

Specification

| Txuj | DIN2391 DIN1630 EN10305 DIN2445 JIS G3445 SAE J524 |

| Qib | ST35/E235 ST37.4 ST45/E255 ST52/E355 |

| Kev Xa Khoom | NBK(+N) BK(+C) GBK(+A) BKW(+LC) BKS(+SR) |

| Loj | OD: 4-219mm Thickness 0.5-35mm, Ntev: 3m, 5.8,6 lossis raws li xav tau |

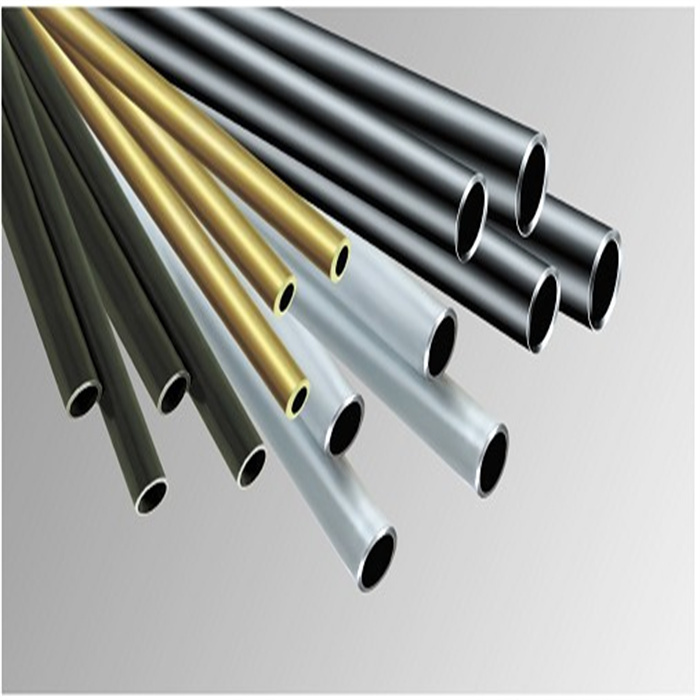

| Ua kom tiav | Galvanized nto (Sliver / Yellow / Colourful) Zinc txheej ntawm 8-12um |

| Daim ntawv thov | Hydraulic System;Tsheb / tsheb npav;tsheb tsim kho |

| Lub sij hawm xa tuaj | A.3 hnub yog tias qhov zoo no yog cov khoom lag luam. B. Txog 30 hnub raws li qhov ntau |

| HYDRAULIC PRECSION STEEL TUBE hauv Tshuag | ||||||||||

| OD | Thickness (hli) | |||||||||

| mm |

| |||||||||

| 4 | 4 * 1 |

|

|

|

|

|

|

|

|

|

| 6 | 6 * 1 | 6 * 1.5 hli | 6 * 2 |

|

|

|

|

|

|

|

| 8 | 8 * 1 | 8 * 1.5 hli | 8 * 2 |

|

|

|

|

|

|

|

| 10 | 10 * 1 | 10 * 1.5 hli | 10 * 2 | 10 * 2.5 hli |

|

|

|

|

|

|

| 12 | 12 * 1 | 12 * 1.5 hli | 12 * 2 | 12 * 2.5 hli | 12 * 3 |

|

|

|

|

|

| 14 | 14 * 1 | 14 * 1.5 hli | 14 * 2 | 14 * 2.5 hli | 14 * 3 |

|

|

|

|

|

| 15 | 15 * 1 | 15 * 1.5 hli | 15 * 2 | 15 * 2.5 hli | 15 * 3 | 15 * 3.5 hli |

|

|

|

|

| 16 | 16 * 1 | 16 * 1.5 hli | 16 * 2 | 16 * 2.5 hli | 16 * 3 | 16 * 3.5 hli | 16 * 4 | 16 * 4.5 hli |

|

|

| 18 | 18 * 1 | 18 * 1.5 hli | 18 * 2 | 18 * 2.5 hli | 18 * 3 | 18 * 3.5 hli | 18 * 4 | 18 * 4.5 hli |

|

|

| 20 | 20 * 1 | 20 * 1.5 hli | 20 * 2 | 20 * 2.5 hli | 20 * 3 | 20 * 3.5 hli | 20 * 4 | 20 * 4.5 hli | 20 * 5 |

|

| 22 | 22 * 1 | 22 * 1.5 hli | 22 * 2 | 22 * 2.5 hli | 22 * 3 | 22 * 3.5 hli | 22 * 4 | 22 * 4.5 hli | 22 * 5 |

|

| 25 | 25 * 1 | 25 * 1.5 hli | 25 * 2 | 25 * 2.5 hli | 25 * 3 | 25 * 3.5 hli | 25 * 4 | 25 * 4.5 hli | 25 * 5 |

|

| 28 | 28 * 1 | 28 * 1.5 hli | 28 * 2 | 28 * 2.5 hli | 28 * 3 | 28 * 3.5 hli | 28 * 4 | 28 * 4.5 hli | 28 * 5 |

|

| 30 | 30 * 1 | 30 * 1.5 hli | 30 * 2 | 30 * 2.5 hli | 30 * 3 | 30 * 3.5 hli | 30 * 4 | 30 * 4.5 hli | 30 * 5 | 30 * 6 |

| 32 |

| 32 * 1.5 hli | 32 * 2 | 32 * 2.5 hli | 32 * 3 | 32 * 3.5 hli | 32 * 4 | 32 * 4.5 hli | 32 * 5 | 32 * 6 |

| 34 |

| 34 * 1.5 hli | 34 * 2 | 34 * 2.5 hli | 34 * 3 | 34 * 3.5 | 34 * 4 | 34 * 4.5 | 34 * 5 | 34 * 6 |

| 35 |

| 35 * 1.5 hli | 35 * 2 | 35 * 2.5 hli | 35 * 3 | 35 * 3.5 hli | 35 * 4 | 35 * 4.5 hli | 35 * 5 | 35 * 6 |

| 38 |

|

| 38 * 2 | 38 * 2.5 hli | 38 * 3 | 38 * 3.5 hli | 38 * 4 | 38 * 4.5 hli | 38 * 5 | 38 * 6 |

| 40 |

|

| 40 * 2 | 40 * 2.5 hli | 40 * 3 | 40 * 3.5 hli | 40 * 4 | 40 * 4.5 hli | 40 * 5 | 40 * 6 |

| 42 |

|

| 42 * 2 | 42 * 2.5 hli | 42 * 3 | 42 * 3.5 hli | 42 * 4 | 42 * 4.5 hli | 42 * 5 | 42 * 6 |

| 45 |

|

| 45 * 2 | 45 * 2.5 hli | 45 * 3 | 45 * 3.5 hli | 45 * 4 | 45 * 4.5 hli | 45 * 5 | 45 * 6 |

| 46 |

|

| 46 * 2 | 46 * 2.5 hli | 46 * 3 | 46 * 3.5 hli | 46 * 4 | 46 * 4.5 hli | 46 * 5 | 46 * 6 |

| 48 |

|

| 48 * 2 | 48 * 2.5 hli | 48 * 3 | 48 * 3.5 hli | 48 * 4 | 48 * 4.5 hli | 48 * 5 | 48 * 6 |

| 50 |

|

| 50 * 2 | 50 * 2.5 hli | 50 * 3 | 50 * 3.5 hli | 50 * 4 | 50 * 4.5 hli | 50 * 5 | 50 * 6 |

| 54 |

|

|

| 54 * 2.5 hli | 54 * 3 | 54 * 3.5 hli | 54 * 4 | 54 * 4.5 hli | 54 * 5 | 54 * 6 |

| 60 |

|

|

| 60 * 2.5 hli | 60 * 3 | 60 * 3.5 hli | 60 * 4 | 60 * 4.5 hli | 60 * 5 | 60 * 6 |

| 65 |

|

|

|

| 65 * 3 | 65 * 3.5 hli | 65 * 4 | 65 * 4.5 hli | 65 * 5 | 65 * 6 |

| 75 |

|

|

|

|

| 75 * 3.5 hli | 75 * 4 | 75 * 4.5 hli | 75 * 5 | 75 * 6 |

| 76 |

|

|

|

|

|

| 76 * 4 | 76 * 4.5 hli | 76 * 5 | 76 * 6 |

| 89 |

|

|

|

|

|

|

|

|

| 89 * 6 |

| Nco tseg: Peb tuaj yeem tsim lwm qhov ntau thiab tsawg raws li koj xav tau.Kev kho deg: ci, Galvanized, Phosphating thiab lwm yam. | ||||||||||

Tshuaj muaj pes tsawg leeg

| Qib Steel | C | Si | Mn | P | S | Al | |

| Lub npe | Tsis muaj. | max | max | max | max | max | max |

| E215 | 1.0212 ib | 0.1 | 0.05 Nws | 0.7 ua | 0.025 ib | 0.015 ib | 0.025 ib |

| E235 | 1.0308 Nws | 0.17 ib | 0.35 Nws | 1.2 | 0.025 ib | 0.015 ib | — |

| E355 | 1.058 ib | 0.22 | 0.55 ib | 1.6 | 0.025 ib | 0.015 ib | — |

| TSI 35 | 1.0308 Nws | 0.17 ib | 0.35 Nws | 0.4 (min) | 0.025 ib | 0.025 ib | — |

| TSI 45 | 1, 0408 | 0.21 ib | 0.35 Nws | 0.4 (min) | 0.025 ib | 0.025 ib | — |

| TSI 52 | 1.058 ib | 0.22 | 0.55 ib | 1.6 | 0.025 ib | 0.025 ib | — |

Mechanical zog

| Qib Steel | Yield zog (Mpa) | Tensile zog (Mpa) | Elongation (%) | |

| Lub npe | Tsis muaj. | ReH (min) | Rm (min) | A(min) |

| E215 | 1.0212 ib | 215 | 290-430 Nws | 30 |

| E235 | 1.0308 Nws | 235 | 340-480 Nws | 25 |

| E355 | 1.058 ib | 355 | 490-630 Nws | 22 |

| TSI 35 | 1.0308 Nws | 235 | 340-480 Nws | 25 |

| TSI 45 | 1, 0408 | 255 | 440-570 Nws | 21 |

| TSI 52 | 1.058 ib | 355 | 490-630 Nws | 22 |

Ua siab ntev

| OD | Kev kam rau siab | Tshwj xeeb kam rau ua | ||

|

| GB / T3639 | DIN2391 | OD | WT |

| 4 hli-20mm | ± 0.10 hli | ± 0.08 hli | ± 0.05 hli | ± 0.05 hli |

| 20mm-30mm | ± 0.10 hli | ± 0.08 hli | ± 0.08 hli | ± 0.08 hli |

| 31mm-40mm | ± 0.15 hli | ± 0.15 hli | ± 0.10 hli | ± 0.08 hli |

| 41mm-60mm | ± 0.20 hli | ± 0.20 hli | ± 0.15 hli | ± 0.15 hli |

| 61mm-80mm | ± 0.30 hli | ± 0.30 hli | ± 0.20 hli | ± 0.20 hli |

| 81mm-120mm | ± 0.45 hli | ± 0.45 hli | ± 0.30 hli | ± 0.30 hli |

Kev Xa Khoom

| Lub npe | Cim | Kev piav qhia |

| Txias tiav (nyuaj) | BK (+C) | Cov raj tsis tau txais kev kho cua sov tom qab qhov kawg txias txias thiab, yog li, muaj kev tiv thaiv siab heev rau deformation. |

| Cold tiav (Soft) | BKW | Kev kho cua sov zaum kawg yog ua raws li kev kos duab txias uas muaj kev txwv tsis pub deformation.Kev tsim nyog ntxiv tso cai rau qee qhov kev ua kom txias (xws li khoov, nthuav dav) |

| (+ LC) | ||

| Txias tiav thiab kev ntxhov siab | BKS(+SR) | Kev kho cua sov yog siv tom qab lub caij txias kawg.Raws li cov txheej txheem ua haujlwm tsim nyog, qhov nce ntxiv ntawm cov kev ntxhov siab uas cuam tshuam cuam tshuam ua rau ob qho tib si tsim thiab machining mus rau ib qib twg. |

| Annealed | GBK (+A) | Cov txheej txheem txias txias kawg yog ua raws li kev sib tsoo hauv qhov chaw tswj tau. |

| Li qub | NBK (+ N) | Cov txheej txheem txias txias kawg yog ua raws li los ntawm annealing saum toj kawg nkaus transformation point nyob rau hauv ib qho chaw tswj. |

Quality Assurance

1. nruj raws li DIN2391/EN10305 lossis lwm yam qauv.

2. Qauv: Qauv yog pub dawb rau kev kuaj.

3. Kev sim: ntsev tsuag tshuaj ntsuam / Tensile xeem / Eddy tam sim no / Tshuaj muaj pes tsawg leeg kuaj raws li cov neeg siv khoom thov

4.Certificate: IATF16949, ISO9001, SGS thiab lwm yam.

5.EN 10204 3.1 Ntawv pov thawj

Daim ntawv thov

Pob khoom