GCr15 SAE52100 100Cr6 SUJ2 bearing steel raj

Khoom Paub meej

DIN1.3505 bearing steel yog ib hom zoo alloy bearing steel, uas belongs rau high carbon thiab tsawg alloy steel uas muaj chromium.1.3505 Roj quench thiab temper quench hardness 28-34 HRc.DIN W-NR 1.3505 Steel annealed xa khoom hardened tsawg dua 250 HB.

DIN1.3505 steel yog dav siv nyob rau hauv ntau yam kev siv ntawm rotating machinery bearings.Cov kev siv xws li lub cev valve, twj thiab fittings, siab loads ntawm lub log, bolts, studs, gears, internal combustion engines.Cov npas hlau, cov menyuam thiab lub tes tsho ntawm lub tes tsho ntawm kev sib kis ntawm cov hluav taws xob locomotives, cov cuab yeej siv tshuab, tsheb laij teb, cov khoom siv dov, txoj kev tsheb ciav hlau, tsheb ciav hlau thiab cov tshuab mining.

Tsis muaj

| Loj | HloovYeeb | OD 10mm-130mm WT2mm-20mm |

| Phaj / tiaj / thaivtuav | Thickness 6mm-500mm | |

| Dav 20mm-1000mm | ||

| Kev kho cua sov | normalized;Annealed;Quenched;Tempered | |

| Deg mob | Dub;Peeled;Polished;Tshuab;Sib tsoo;tig;Milled | |

| Kev xa khoom | Forged;Kub dov;Txias kos | |

| Kuaj | Tensile zog, Yield zog, elongation, cheeb tsam ntawm txo, cuam tshuam tus nqi, hardness, grain loj, ultrasonic kuaj, US soj ntsuam, magnetic particle kuaj, thiab lwm yam. | |

| Cov nqe lus them nqi | T / T; L / C; / Nyiaj Gram / Paypal | |

| Cov ntsiab lus lag luam | FOB;CIF;C&F;lwm.. | |

| Lub sij hawm xa tuaj | 30-45 hnub | |

Sib npaug Bearing Steel Qib

| Lub teb chaws | German | Nyiv | Askiv | CHN | Teb chaws USA |

| Txuj | TIAB SA 17230 | JIS G4805 | SIB 970 |

| ASTM A 295 Cov Lus Qhia Tshwj Xeeb |

| Qib | 100Cr6/1.3505 | SUJ 2 | 535A99/EN31 | Gcr15 | 5 2100 |

Chemical Composition (%)

| Grade | C | Si | Mn | P | S | Cr | Mo | Ni |

| EN31/535A99 | 0.95-1.10 Nws | 0.10-0.35 dr hab | 0.25-0.40 Nws | 0.04 ib | 0.05 Nws | 1.20-1.60 Nws | / | / |

| 52100/1.3505 | 0.93-1.05 Nws | 0.15-0.35 dr hab | 0.25-0.45 Nws | 0.025 ib | 0.015 ib | 1.35-1.60 Nws | 0.10 | 0.30 Nws |

| SUJ 2 | 0.95-1.10 Nws | 0.15-0.35 dr hab | 0.50 ib | 0.025 ib | 0.025 ib | 1.30-1.60 Nws | 0.08 ib | 0.25 |

| GCr15 | 0.95-1.05 Nws | 0.15-0.35 dr hab | 0.25-0.45 Nws | 0.025 ib | 0.025 ib | 1.40-1.65 Nws | 0.10 | 0.30 Nws |

Mechanical Properties

| Hlau Lub Npe (Steel Number) | Tensile zog (MPa) | Yield zog (MPa), ≥ | Elongation (%, ≥) | Hardness (HWB,≤) |

| 1.3505 Nws | 1080-1470 Ib | 835 ib | 9 | 207(Annealed) |

|

| 830-1130 Nws | 590 ua | 10 | 241(Annealed) |

Kev kho cua sov

Annealing : Maj mam kub rau 872 ° C (1600 ° F) thiab maj mam txias kom txo tau txias ua hauj lwm los yog machining stresses.Txawv annealing txoj kev yuav muab sib txawv hardness.1.3505 Bearing steel yuav tau hardness MAX 248 HB.

quenching: Kub maj mam mus rau 816 ° C (1500 ° F) thiab quench nyob rau hauv cov roj kom tau ib tug hardness ntawm 62 - 66 HRc.Kub kub tempering: 650-700 ℃, cua txias, hardness 22-30HRC.Tsawg kub tempering: 150-170 ℃, hardness: 61-66 HRC.

Daim ntawv thov

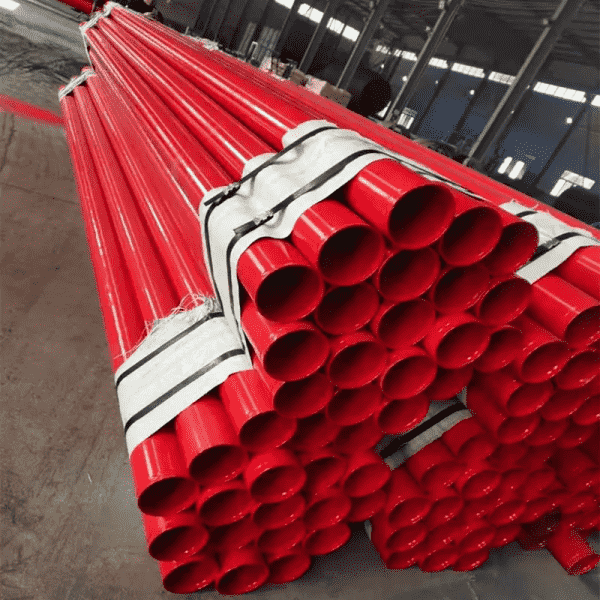

DIN1.3505 Alloy Seamless Tube & Yeeb Nkab Rau Cov Kabmob

1.Rau ua txhua yam ntawm cov kabmob nplhaib thiab cov khoom dov, xws li steel pob cov menyuam thiab ferrule ntawm sab hauv combustion cav, hluav taws xob maus taus, automonilrd tsheb laij teb, tshuab cuab yeej, dov zeb, tho txawv tshuab, mining machinery, general machinery, siab load thiab siab. ceev roating mechanical kis kabmob.

2.Qee zaum kuj siv los ua cov cuab yeej, xws li pumching tuag thiab ntsuas cov cuab yeej.

3.Lub tsheb thiab dav hlau kev lag luam siv DIN1.3505 rau ntau daim ntawv thov sib txawv suav nrog.

4. Anti-kev sib txhuam bearings

5.Mill Rolls

6. Kais

7. Punches

8. Cov khoom siv dav hlau