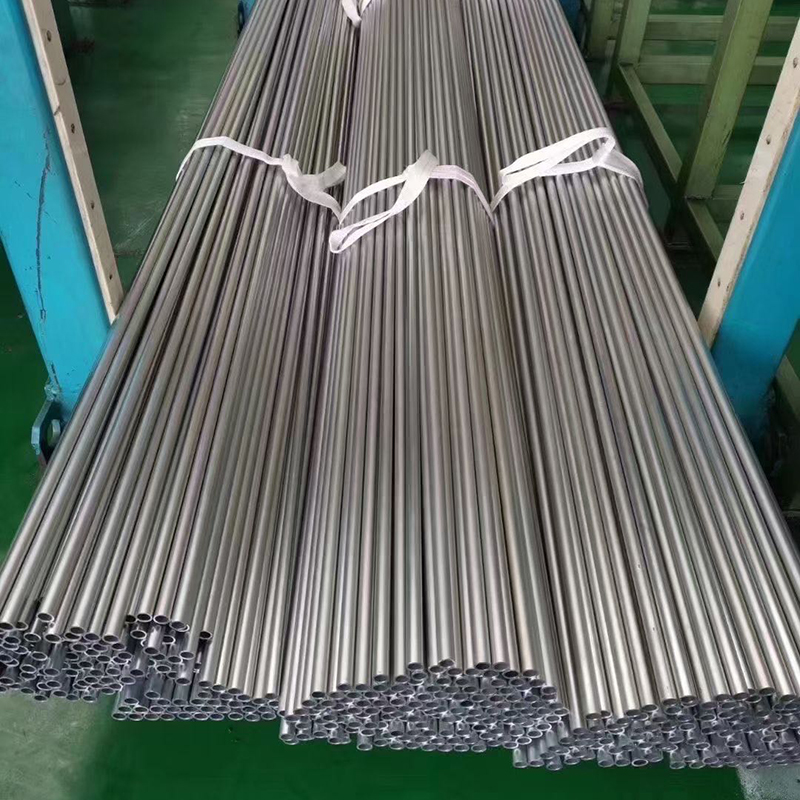

JIS3445 Stkm11A 12A 13A Auto Tube

Peb txaus siab rau cov neeg siv khoom siab thiab kev lees paub dav vim peb pheej nrhiav kev ua haujlwm zoo ntawm cov khoom lag luam thiab kev pabcuam rau JIS3445 Stkm11A 12A 13A Auto Tube, Tsis tas li ntawd, peb yuav qhia cov neeg siv khoom kom zoo txog daim ntawv thov cov txheej txheem los txais peb cov kev daws teeb meem thiab txoj kev xaiv cov khoom tsim nyog.

Peb txaus siab rau cov neeg siv khoom siab thiab kev lees txais dav vim peb pheej nrhiav kev ua haujlwm siab ntawm cov khoom thiab kev pabcuam raustkm11a cev, Stkm11a Hlau Tube, Peb tau teeb tsa "ua tus kws kho mob muaj txiaj ntsig kom ua tiav kev txhim kho txuas ntxiv thiab kev tsim kho tshiab" raws li peb cov lus qhia.Peb xav qhia peb cov kev paub dhau los nrog cov phooj ywg hauv tsev thiab txawv teb chaws, ua ib txoj hauv kev los tsim lub ncuav mog qab zib loj nrog peb kev sib koom tes.Peb muaj ntau tus neeg paub txog R & D thiab peb txais tos OEM xaj.

Nta

Khoom Qib:

STKM 11A 12A 12B 12C 13A 13B 13C 14A 14B 14C 15A 15C thiab lwm yam.

Kev kho deg:

1. Bared

2.Black Painted (cov kua roj vanish txheej)

3. Galvanized

4. Yog '

5.Raws li cov neeg siv khoom.

JIS G3445 Precision steel hlab yog tsuas yog siv nyob rau hauv tsheb thiab precision machinery qhov chaw rau tsheb thiab lub tog raj kheej.kev siv siab, thiab tseem siv rau kev thauj cov chav, dej, cov kav dej.

Tshuaj muaj pes tsawg leeg

| Qib | Lub npe | Unit (%) | ||||||

| C | Si | Mn | P | S | Nb sau V | |||

| Qib 11 | A | STKM 11A | 0.12 max. | 0.35 max. | 0.60 max. | 0.040 max. | 0.040 max. | - |

| Qib 12 | A | STKM 12A | 0.20 max. | 0.35 max. | 0.6 max. | 0.04 max. | 0.04 max. | |

| B | STKM 12B | |||||||

| C | STKM 12C | |||||||

| Qib 13 | A | STKM 13A | 0.25 max. | 0.35 max. | 0.30-0.90 Nws | 0.040 max. | 0.040 max. | - |

| B | STKM 13B | |||||||

| C | STKM 13C | |||||||

| Qib 14 | A | STKM 14A | 0.30 max. | 0.35 max. | 0.30-1.00 Nws | 0.040 max. | 0.040 max. | - |

| B | STKM 14B | |||||||

| C | STKM 14 C | |||||||

| Qib 15 | A | STKM 15A | 0.25-0.35 Nws | 0.35 max. | 0.30-1.00 Nws | 0.040 max. | 0.040 max. | - |

| C | STKM 15 C | |||||||

| Qib 16 | A | STKM 16A | 0.35-0.45 Nws | 0.40 max. | 0.40-1.00 Nws | 0.040 max. | 0.040 max. | - |

| C | STKM 16C | |||||||

| Qib 17 | A | STKM 17A | 0.45-0.55 Nws | 0.40 max. | 0.40-1.00 Nws | 0.040 max. | 0.040 max. | - |

| C | TSI 17C | |||||||

| Qib 18 | A | STKM 18A | 0.18 max. | 0.55 max. | 1.50 max. | 0.040 max. | 0.040 max. | - |

| B | STKM 18B | |||||||

| C | STKM 18C | |||||||

| Qib 19 | A | STKM 19A | 0.25 max. | 0.55 max. | 1.50 max. | 0.040 max. | 0.040 max. | - |

| C | STKM 19C | |||||||

| Qib 20 | A | STKM 20A | 0.25 max. | 0.55 max. | 1.60 max. | 0.040 max. | 0.040 max. | 0.15 max |

Mechanical zog

| Qib Steel | Yield zog (Mpa) | Tensile zog (Mpa) | Elongation (%) | |

| Lub npe | Tsis muaj. | ReH (min) | Rm (min) | A(min) |

| STKM 11A |

| _ | 290 | 35 |

| STKM 12A |

| 175 | 340 | 35 |

| STKM 12B |

| 275 | 390 | 25 |

| STKM 12C |

| 355 | 4700 ib | 20 |

| STKM 13A |

| 215 | 370 | 30 |

| STKM 11B |

| 305 | 440 | 20 |

| STKM11C |

| 380 | 510 | 15 |

Ua siab ntev

| SIZE | Kev kam rau siab | Tshwj xeeb kam rau ua | ||

| OD | WT | OD | WT | |

| 4 hli-20mm | ± 0.25 hli | <3mm ± 0.3mm;

≥3mm ± 10%

| ± 0.05 hli | ± 0.05 hli |

| 20mm-30mm | ± 0.25 hli | ± 0.08 hli | ± 0.08 hli | |

| 31mm-40mm | ± 0.25 hli | ± 0.10 hli | ± 0.08 hli | |

| 41mm-49 hli | ± 0.25 hli | ± 0.15 hli | ± 0.15 hli | |

| 50mm-80mm | ± 0.5% | ± 0.20 hli | ± 0.20 hli | |

| 81mm-120mm | ± 0.5% | ± 0.30 hli | ± 0.30 hli | |

Kev xa khoom

| Lub npe | Cim | Kev piav qhia |

| Txias tiav (nyuaj) | BK (+C) | Cov raj tsis tau txais kev kho cua sov tom qab qhov kawg txias txias thiab, yog li, muaj kev tiv thaiv siab heev rau deformation. |

| Cold tiav (Soft) | BKW | Kev kho cua sov zaum kawg yog ua raws li kev kos duab txias uas muaj kev txwv tsis pub deformation.Kev tsim nyog ntxiv tso cai rau qee qhov kev ua kom txias (xws li khoov, nthuav dav) |

| (+ LC) | ||

| Txias tiav thiab kev ntxhov siab | BKS(+SR) | Kev kho cua sov yog siv tom qab lub caij txias kawg.Raws li cov txheej txheem tsim nyog, qhov nce ntawm cov kev ntxhov siab uas cuam tshuam cuam tshuam ua rau ob qho tib si tsim thiab machining mus rau ib qho twg. |

| Annealed | GBK (+A) | Cov txheej txheem txias txias kawg yog ua raws li kev sib tsoo hauv qhov chaw tswj tau. |

| Li qub | NBK (+ N) | Cov txheej txheem txias txias kawg yog ua raws li los ntawm annealing saum toj kawg nkaus transformation point nyob rau hauv ib qho chaw tswj. |

| High Precision Steel Tubes hauv Tshuag | ||||||||||

| OD | Thickness (hli) | |||||||||

| mm | ||||||||||

| 4 | 4 * 1 | |||||||||

| 6 | 6 * 1 | 6 * 1.5 hli | 6 * 2 | |||||||

| 8 | 8 * 1 | 8 * 1.5 hli | 8 * 2 | |||||||

| 10 | 10 * 1 | 10 * 1.5 hli | 10 * 2 | 10 * 2.5 hli | ||||||

| 12 | 12 * 1 | 12 * 1.5 hli | 12 * 2 | 12 * 2.5 hli | 12 * 3 | |||||

| 14 | 14 * 1 | 14 * 1.5 hli | 14 * 2 | 14 * 2.5 hli | 14 * 3 | |||||

| 15 | 15 * 1 | 15 * 1.5 hli | 15 * 2 | 15 * 2.5 hli | 15 * 3 | 15 * 3.5 hli | ||||

| 16 | 16 * 1 | 16 * 1.5 hli | 16 * 2 | 16 * 2.5 hli | 16 * 3 | 16 * 3.5 hli | 16 * 4 | 16 * 4.5 hli | ||

| 18 | 18 * 1 | 18 * 1.5 hli | 18 * 2 | 18 * 2.5 hli | 18 * 3 | 18 * 3.5 hli | 18 * 4 | 18 * 4.5 hli | ||

| 20 | 20 * 1 | 20 * 1.5 hli | 20 * 2 | 20 * 2.5 hli | 20 * 3 | 20 * 3.5 hli | 20 * 4 | 20 * 4.5 hli | 20 * 5 | |

| 22 | 22 * 1 | 22 * 1.5 hli | 22 * 2 | 22 * 2.5 hli | 22 * 3 | 22 * 3.5 hli | 22 * 4 | 22 * 4.5 hli | 22 * 5 | |

| 25 | 25 * 1 | 25 * 1.5 hli | 25 * 2 | 25 * 2.5 hli | 25 * 3 | 25 * 3.5 hli | 25 * 4 | 25 * 4.5 hli | 25 * 5 | |

| 28 | 28 * 1 | 28 * 1.5 hli | 28 * 2 | 28 * 2.5 hli | 28 * 3 | 28 * 3.5 hli | 28 * 4 | 28 * 4.5 hli | 28 * 5 | |

| 30 | 30 * 1 | 30 * 1.5 hli | 30 * 2 | 30 * 2.5 hli | 30 * 3 | 30 * 3.5 hli | 30 * 4 | 30 * 4.5 hli | 30 * 5 | 30 * 6 |

| 32 | 32 * 1.5 hli | 32 * 2 | 32 * 2.5 hli | 32 * 3 | 32 * 3.5 hli | 32 * 4 | 32 * 4.5 hli | 32 * 5 | 32 * 6 | |

| 34 | 34 * 1.5 hli | 34 * 2 | 34 * 2.5 hli | 34 * 3 | 34 * 3.5 | 34 * 4 | 34 * 4.5 | 34 * 5 | 34 * 6 | |

| 35 | 35 * 1.5 hli | 35 * 2 | 35 * 2.5 hli | 35 * 3 | 35 * 3.5 hli | 35 * 4 | 35 * 4.5 hli | 35 * 5 | 35 * 6 | |

| 38 | 38 * 2 | 38 * 2.5 hli | 38 * 3 | 38 * 3.5 hli | 38 * 4 | 38 * 4.5 hli | 38 * 5 | 38 * 6 | ||

| 40 | 40 * 2 | 40 * 2.5 hli | 40 * 3 | 40 * 3.5 hli | 40 * 4 | 40 * 4.5 hli | 40 * 5 | 40 * 6 | ||

| 42 | 42 * 2 | 42 * 2.5 hli | 42 * 3 | 42 * 3.5 hli | 42 * 4 | 42 * 4.5 hli | 42 * 5 | 42 * 6 | ||

| 45 | 45 * 2 | 45 * 2.5 hli | 45 * 3 | 45 * 3.5 hli | 45 * 4 | 45 * 4.5 hli | 45 * 5 | 45 * 6 | ||

| 46 | 46 * 2 | 46 * 2.5 hli | 46 * 3 | 46 * 3.5 hli | 46 * 4 | 46 * 4.5 hli | 46 * 5 | 46 * 6 | ||

| 48 | 48 * 2 | 48 * 2.5 hli | 48 * 3 | 48 * 3.5 hli | 48 * 4 | 48 * 4.5 hli | 48 * 5 | 48 * 6 | ||

| 50 | 50 * 2 | 50 * 2.5 hli | 50 * 3 | 50 * 3.5 hli | 50 * 4 | 50 * 4.5 hli | 50 * 5 | 50 * 6 | ||

| 54 | 54 * 2.5 hli | 54 * 3 | 54 * 3.5 hli | 54 * 4 | 54 * 4.5 hli | 54 * 5 | 54 * 6 | |||

| 60 | 60 * 2.5 hli | 60 * 3 | 60 * 3.5 hli | 60 * 4 | 60 * 4.5 hli | 60 * 5 | 60 * 6 | |||

| 65 | 65 * 3 | 65 * 3.5 hli | 65 * 4 | 65 * 4.5 hli | 65 * 5 | 65 * 6 | ||||

| 75 | 75 * 3.5 hli | 75 * 4 | 75 * 4.5 hli | 75 * 5 | 75 * 6 | |||||

| 76 | 76 * 4 | 76 * 4.5 hli | 76 * 5 | 76 * 6 | ||||||

| 89 | 89 * 6 | |||||||||

| Nco tseg: Peb tuaj yeem tsim lwm qhov ntau thiab tsawg raws li koj xav tau.Kev kho deg: ci, Galvanized, Phosphate thiab lwm yam. | ||||||||||

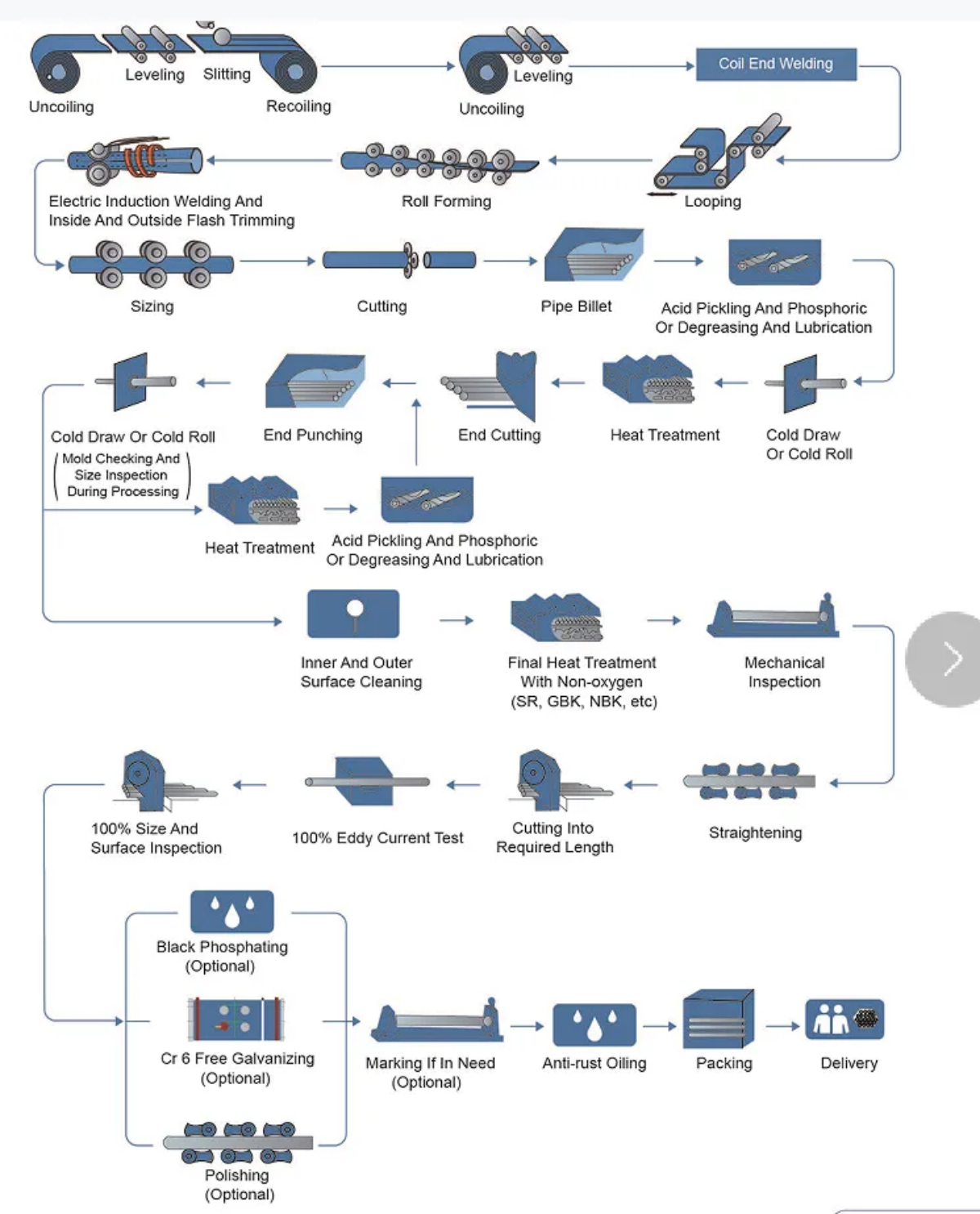

Txheej txheem tsim khoom

Qhov zoo

Ntxiv dag zog rau kev tshuaj xyuas cov khoom nyob rau hauv txhua theem ntawm kev tsim khoom, nruab nrog cov khoom siv ua tiav: kev ntsuas tsis muaj kev puas tsuaj tam sim no, kev kub siab tiv thaiv kev sim tshuab, universal mechanical tensile testing machine, bending flattening flares testing machine, cleanliness analyzer, metal element analyzer, etc. Ua tau raws li cov khoom siv kho tshuab ntawm cov khoom, cov txheej txheem kev ntsuas kev ua tau zoo, muab lub zog lav rau cov khoom tsim nyog.

Kev ruaj ntseg zoo

1. nruj raws li JIS G3445 Standard los yog lwm yam qauv.

2. Qauv: Qauv yog pub dawb rau kev kuaj.

3. Kev sim: ntsev tsuag tshuaj ntsuam / Tensile xeem / Eddy tam sim no / Tshuaj muaj pes tsawg leeg kuaj raws li cov neeg siv khoom thov

4.Certificate: IATF16949, ISO9001, SGS thiab lwm yam.

5.EN 10204 3.1 Ntawv pov thawj

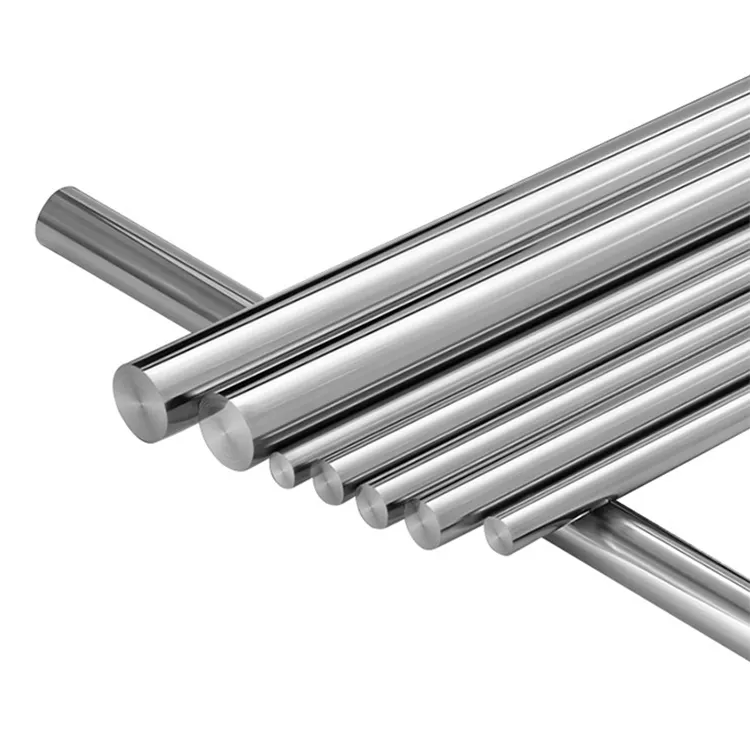

STKM11A yog cov khoom siv qib hauv Nyij Pooj, feem ntau xa mus rau carbon steel kav rau cov khoom siv tshuab.

Cov ntsiab lus ntawm alloy:

C: 0.12% Si: 0.35% Mn: 0.60% P: 0.04% S: 0.04% 4. Mechanical zog:

Lub hardness thiab hardness ntawm STKM11a steel yeeb nkab yog 950HV, thiab lub zog tensile yog txiav txim los ntawm nws lub zog σ B (MPa): ≥ 295 elongation δ /% : Ntev ≥ 35, transverse ≥ 30 steel qauv yuav tsum xyuam xim rau hardness.STKM11 yog cov pa roj carbon ntau, thiab STKM11A yog qib steel rau carbon steel kav siv hauv cov khoom siv tshuab.Nws yog qib Japanese sib raug rau Tuam Tshoj lub teb chaws tus qauv steel yeeb nkab 10 # steel.

Peb txaus siab rau cov neeg siv khoom siab thiab kev lees paub dav vim peb pheej nrhiav kev ua haujlwm siab ntawm ob qho tib si ntawm cov khoom lag luam thiab kev pabcuam rau Quoted nqe rau JIS3445 Stkm11A 12A 13A Auto Tube, Tsis tas li ntawd, peb yuav qhia cov neeg siv khoom kom zoo txog daim ntawv thov kev coj ua. peb cov kev daws teeb meem thiab txoj hauv kev xaiv cov khoom tsim nyog.

Quoted nqe rau Tuam Tshoj Seamless Steel Yeeb Nkab thiab Yeeb Nkab Fitting, Peb teem "ua ib tug creditable practitioner kom ua tiav kev nruam kev loj hlob thiab innovation" raws li peb motto.Peb xav qhia peb cov kev paub dhau los nrog cov phooj ywg hauv tsev thiab txawv teb chaws, ua ib txoj hauv kev los tsim lub ncuav mog qab zib loj nrog peb kev sib koom tes.Peb muaj ntau tus neeg paub txog R & D thiab peb txais tos OEM xaj.