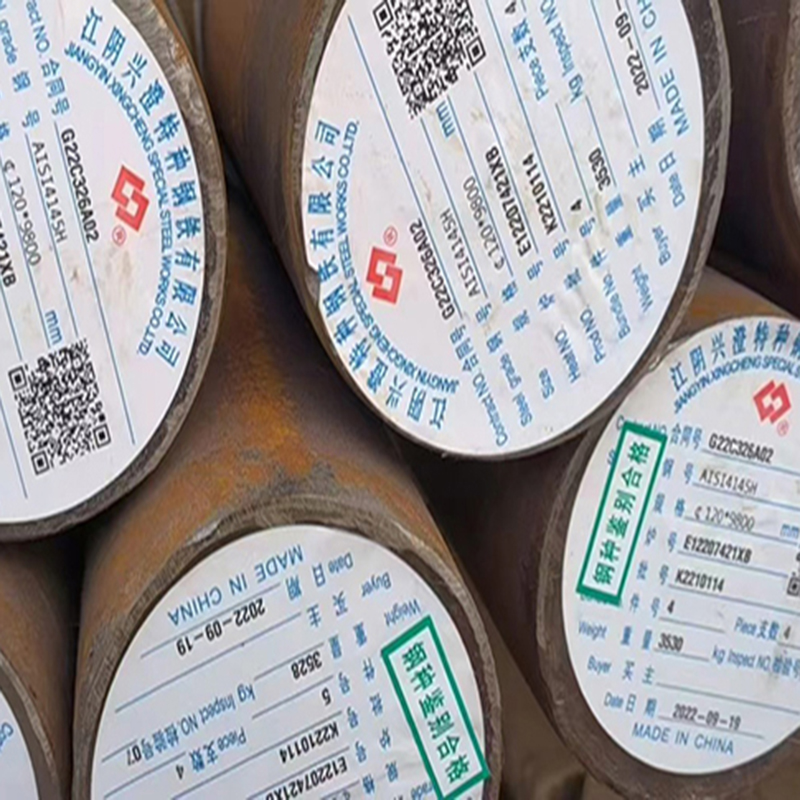

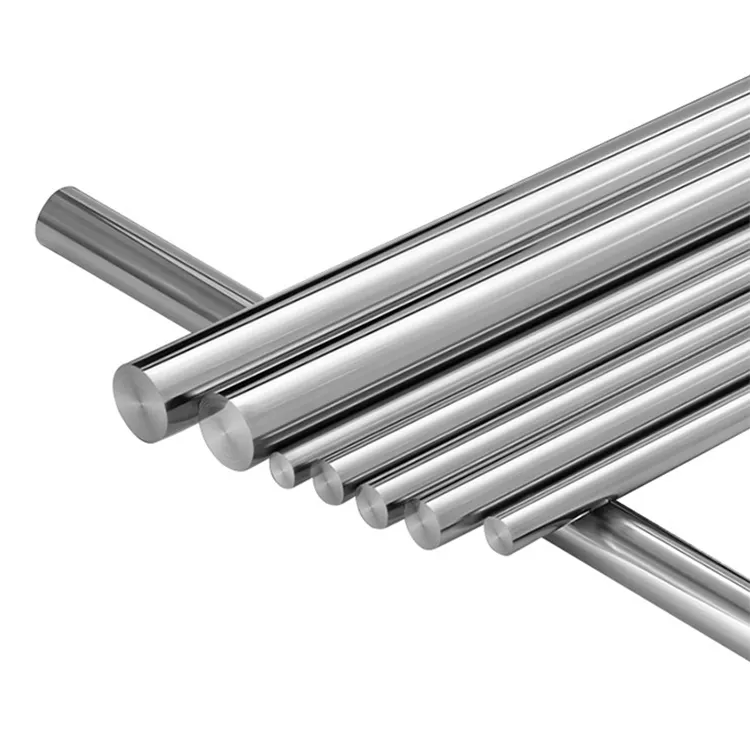

SAE4130 Hlau Round Bar AISI 4130 Alloy Steel Bar

Peb ua raws li kev tswj hwm txoj cai ntawm "Zoo yog qhov tshwj xeeb, Kev Pabcuam yog qhov zoo tshaj plaws, Lub koob npe nrov yog thawj", thiab yuav ua siab dawb tsim thiab sib koom ua tiav nrog txhua tus neeg siv khoom rau SAE4130 Steel Round Bar AISI 4130 Alloy Steel Bar, Peb kuj tseem niaj hnub yos hav zoov los tsim kev sib raug zoo nrog cov neeg muag khoom tshiab los muab kev txhim kho thiab txawj ntse rau peb cov neeg siv khoom muaj txiaj ntsig.

Peb ua raws li kev tswj hwm txoj cai ntawm "Zoo yog qhov tshwj xeeb, Kev Pabcuam yog qhov zoo tshaj plaws, Lub koob npe nrov yog thawj", thiab yuav ua siab dawb tsim thiab sib koom ua tiav rau txhua tus neeg siv khoom.4130 Hlau Bar, Peb vam tias peb tuaj yeem tsim kev koom tes ntev nrog txhua tus neeg siv khoom.Thiab vam tias peb tuaj yeem txhim kho kev sib tw thiab ua tiav qhov xwm txheej yeej-yeej ua ke nrog cov neeg siv khoom.Peb zoo siab txais tos cov neeg siv khoom los ntawm thoob plaws lub ntiaj teb los tiv tauj peb rau txhua yam koj xav tau!

Nta

4130 4135 4140 4145H steel tuav yog cov hlau tsis tshua muaj hlau.Lawv yog cov koom nrog Chrome-Molly alloy uas muaj chromium thiab molybdenum ua cov tshuaj ntxiv dag zog.

4130 round steel bar muaj peev xwm ua haujlwm tau zoo, kev ua haujlwm tsawg tsawg, thiab kev qaug zog zoo heev.Nws belongs rau qeb ntawm nruab nrab mus rau siab harden peev xwm steel.Tom qab kev kho cua sov, 4140 muaj lub zog zoo thiab cov khoom siv dav dav, muaj peev xwm ua tau zoo, thiab muaj txiaj ntsig zoo.Kev pabcuam kub yog 427 degrees Celsius.

4140 muaj lub zog siab, muaj peev xwm harden, toughness, thiab deformation thaum quenching.Nws muaj lub zog siab creep thiab endurance lub zog ntawm qhov kub thiab txias.Siv rau kev tsim cov forgings uas yuav tsum tau muaj zog dua thiab loj dua quenched thiab tempered seem tshaj 4135 steel, xws li loj zog rau locomotive traction, booster kis tau tus mob gears, rear qag, txuas rods thiab caij nplooj ntoos hlav clips uas hnyav loaded.

Specification

| Khoom npe | AISI ASTM 4130 4135 4140 Alloy Steel Bar | |

| Khoom siv | ASTM | 4130,4135 4140,4145H |

| DIN | 1.7218 1.7225 1.7220 | |

| GB | 30CrMo 35CrMO 42CrMo | |

| Txuj | GB / T799, ASTM A29, A108, A321, A575, BS970, DIN1652, JIS G4051 | |

| OD | 6mm txog 600mm | |

| Nto | Dub pleev xim rau, liab qab, Polished, Chrome Plated | |

| Specifications | Round bar | 8mm ~ 800 hli |

| Lub kaum sab xis | 3mm * 20mm * 20mm ~ 12mm * 800mm * 800mm | |

| Square bar | 4mm * 4mm ~ 100mm * 100mm | |

| Pav ca | 2 * 10mm ~ 100 * 500mm | |

| Hexagonal | 4mm ~ 800 hli | |

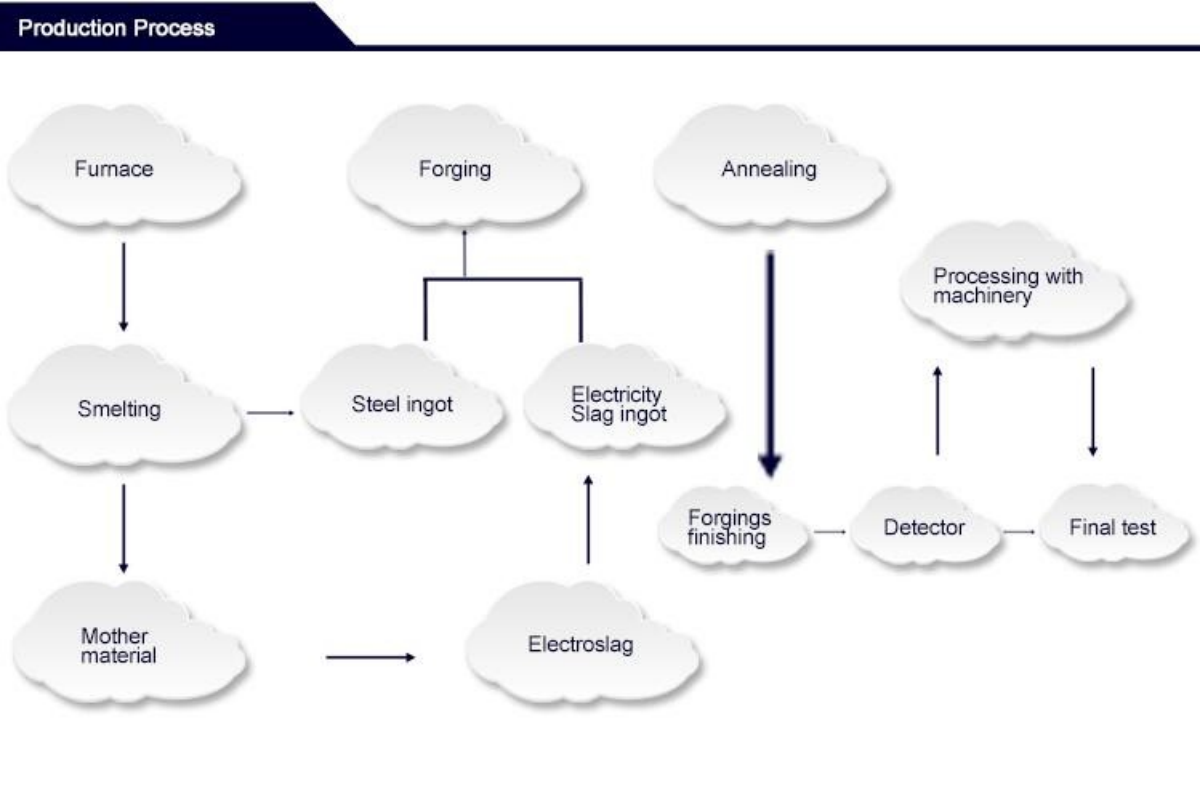

| Txheej txheem | Hluav taws xob rauv melted, forged thiab annealed, round bar tig. | |

| Hardness: | HBS 217Max (Qhov txawv ntawm kev kho cua sov) | |

| UT Test | SEP 1921/84/2 C/c chav. | |

| Ua siab ntev | Dia -0/+ 0 ~ 5mm, Thickness -0/+ 0 ~ 5mm, Dav: -0/+ 0 ~ 10mm. | |

| Ntev | 2m, 4m, 5.8m, 6m, 11.8m, 12m lossis raws li xav tau. | |

| Pob | Seaworthy Ntim. | |

| Sib npaug dIfferent standard | |||

| AISI | GB | DIN | JIS |

| 4 130 | 30 CrMo | 1.7218 ib | SCM420 |

| 4 140 | 42CrMo | 1.7225 (42CrMo4) | SCM440 |

| ib 4135 | 35 crm | 1.7220 (34CrMo4) | SWM 432 |

| 4 145h | — | — | — |

Tshuaj muaj pes tsawg leeg

| Chemical Composition (%) | |||||||

| Qib | C | Si | Mn | P | S | Cr | Mo |

| 4 130 | 0.28-0.33 Nws | 0.15-0.35 dr hab | 0.40-0.60 Nws | ≤ 0.035 | ≤ 0.040 | 0.80-1.10 Nws | 0.15-0.25 dr hab |

| 4 140 | 0.38-0.43 Nws | 0.15-0.35 dr hab | 0.75-1.0 Nws | ≤ 0.035 | ≤ 0.040 | 0.80-1.10 Nws | 0.15-0.25 dr hab |

| ib 4135 | 0.33-0.38 Nws | 0.15-0.35 dr hab | 0.75-0.9 Nws | ≤ 0.035 | ≤ 0.040 | 0.80-1.10 Nws | 0.15-0.25 dr hab |

| 4145 ib | 0.43-0.48 Nws | 0.15-0.35 dr hab | 0.75-1.0 Nws | ≤ 0.035 | ≤ 0.040 | 0.80-1.10 Nws | 0.15-0.25 dr hab |

Mechanical Properties

| Yam ntxwv: |

| 1.Low alloy steel uas muaj molybdenum thiab chromium ua cov neeg ua kom muaj zog; |

| 2.Excellent los ntawm fusion weldability standpoint; |

| 3.The alloy tuaj yeem hardened los ntawm kev kho cua sov. |

Ua siab ntev

| Kev Xa Khoom |

| 1. Kub dov |

| 2. Ua tsaug |

| 3. normalized |

| 4. Quench thiab Tempered |

Cov xwm txheej ntawm kev kho cua sov

1.Annealing: 880 ℃ Rauv txias

2.Normalization: 880 ~ 870 ℃ Cua txias

3. Hardening: 820 ~ 870 ℃ Dej txias

4.Tempering: 550 ~ 650 ℃ ceev txias

Mechanical Properties tuaj yeem tau txais los ntawm kev kho cua sov sib txawv.

Pob

1.By bundles, txhua nras hnyav nyob rau hauv 3 tons, rau me me txheej

txoj kab uas hla puag ncig bar, txhua pob nrog 4 - 8 steel strips.

2.20 feet thawv muaj qhov ntev, ntev hauv qab 6000mm

3.40 feet thawv muaj qhov ntev, ntev hauv qab 12000mm

4.By bulk nkoj, Freight nqi yog tsawg los ntawm bulk cargo, thiab loj

hnyav qhov ntau thiab tsawg tsis tuaj yeem thauj mus rau hauv cov thawv tuaj yeem xa los ntawm cov khoom thauj ntau

Kev ruaj ntseg zoo

1.Strict raws li yuav tsum tau

2. Qauv: Qauv muaj.

3. Kev sim: ntsev tsuag tshuaj ntsuam / Tensile xeem / Eddy tam sim no / Tshuaj muaj pes tsawg leeg kuaj raws li cov neeg siv khoom thov

4.Certificate: IATF16949, ISO9001, SGS thiab lwm yam.

5. EN 10204 3.1 Daim ntawv pov thawj

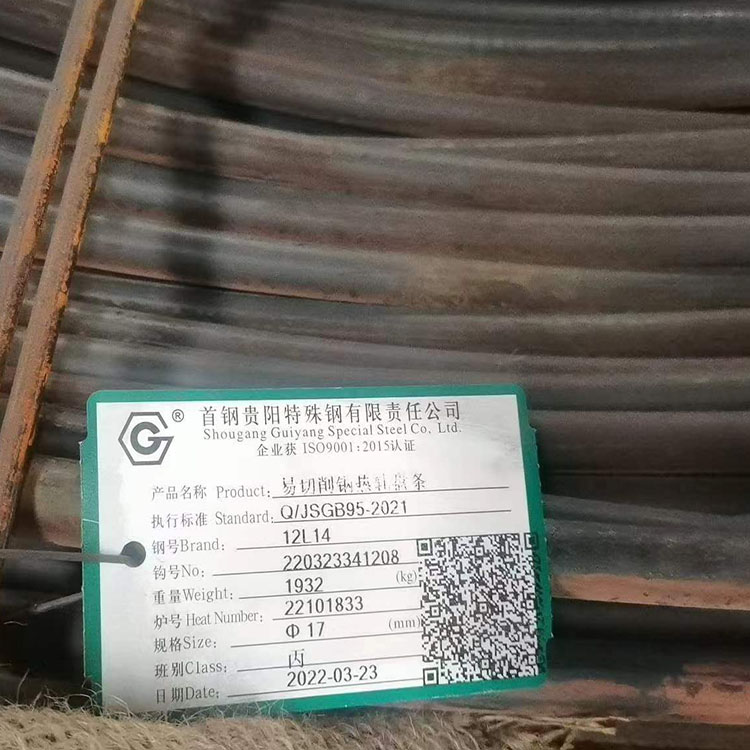

SAE4130 round steel yog cov nqi hlau alloy.Txheem ASTMA29 / A29M-04.Cov khoom lag luam zoo sib xws: 30CrMo Cov khoom lag luam Nyij Pooj: SCM430 (SCM2) Cov khoom lag luam German: 34CrMo4 (1.7220)

4130 structural steel muaj zog thiab toughness, siab hardenability, thiab ib tug tseem ceeb hardenability txoj kab uas hla ntawm 15-70 hli nyob rau hauv roj;Lub zog thermal ntawm cov hlau kuj zoo, nrog rau qhov kub siab txaus lub zog hauv qab 500 ℃, tab sis nws lub zog txo qis ntawm 550 ℃;Thaum cov hlau alloy nyob rau hauv qis qis, vuam yog qhov zoo heev, tab sis thaum nws nyob ze rau lub siab txwv, lub weldability yog nruab nrab, thiab preheating rau saum 175 ℃ yuav tsum tau ua ntej vuam;Cov hlau muaj kev ua haujlwm zoo thiab cov yas me me thaum lub caij txias deformation;Thaum kho cua sov, muaj qhov zoo sib xws ntawm temper brittleness ntawm 300-350 ℃;Muaj ib tug nyiam ua pob dawb.

SAE4130 feem ntau yog siv nyob rau hauv nruab nrab-qhov loj me machinery manufacturing kev lag luam los tsim quenched thiab tempered qhov chaw nrog loj cross-sections uas ua hauj lwm nyob rau hauv kev nyuaj siab, xws li shafts, spindles, thiab siab load tswj log, bolts, ob lub taub hau bolts, zog, lwm yam;Siv nyob rau hauv kev lag luam chemical los tsim cov khoom siv welded, cov qauv welded muaj li ntawm daim hlau thiab cov kav dej, thiab cov twj tso kua mis siab nrog qhov kub tsis tshaj 250 ℃ ua haujlwm hauv nruab nrab uas muaj nitrogen thiab hydrogen;Nyob rau hauv kev lag luam kev lag luam ntawm chav turbines thiab boilers, nws yog siv los tsim cov fasteners rau kev ua hauj lwm hauv qab 450 ℃, flanges thiab flange npog nyob rau hauv siab kub hauv qab 500 ℃.