SAE8620H Steel Round Bar / GB 20CrNiMo Steel Bar

Nta

8620 alloy steel yog tsim los ntawm (hauv kev txiav txim qis ntawm feem pua) hlau, carbon, silicon, molybdenum, manganese, npib tsib xee, chromium, sulfur thiab phosphorus.Cov khoom xyaw no yuav tsum nyob rau hauv qee qhov hnyav feem pua los tsim 8620 alloy.Nws raug pom zoo tias cov hlau yuav hardened los ntawm carburization ua raws li cov roj, tsis zoo li dej, quench.Nws muaj qhov sib luag nruab nrab sib luag rau cov hlau alloys ntawm .28 lb. Ib lub zog tensile - qhov ntau npaum li cas tuaj yeem tuav ua ntej tawg - yog tsawg, ntawm 536.4 MPA.Qhov nruab nrab tensile lub zog ntawm steel alloys yog 758 txog 1882 Mpa.

Thaum 8620 alloy yog carburized kom zoo - rhuab mus rau qhov kub thiab txias thiab tom qab ntawd raug rau tus neeg sawv cev uas muaj cov pa roj carbon monoxide, txheej txheem uas ntxiv cov pa roj carbon ntxiv rau sab nraud ntawm cov hlau, yog li ua rau nws muaj zog - nws yog siv los ua lub tshuab zoo li no. cov khoom xws li iav, crankshafts, thiab iav rings.Carburized 8620 alloy muaj zog thiab ruaj khov, uas yog vim li cas nws thiaj li nyiam rau cov khoom no.

Txheem: ASTM A29 / A29M-2012

Tshuaj muaj pes tsawg leeg

| Cov pa roj carbon C | 0.17-0.23 Nws |

| Silicon Si | 0.15-0.35 Nws |

| Manganese Mn | 0.65 ~ 0.95 hli |

| Sulfur S | ≤ 0.025 |

| Phosphorus P | ≤ 0.025 |

| Chromium Cr | 0.35 ~ 0.65 hli |

| Nickel | 0.35-0.65 Nws |

| Tooj Cu | ≤ 0.025 |

| Molybdenum Cov | 0.15-0.25 dr hab |

Mechanical zog

| Tensile zog σb (MPa) | ≥980 (100) |

| yield zog σs (MPa) | ≥785(80) |

| elongation δ 5 (%) | ≥9 |

| Txo thaj tsam ψ (%) | ≥40 |

| Impact zog Akv (J) | ≥ 47 |

| Qhov cuam tshuam toughness tus nqi α kv (J / cm2) | ≥59(6) |

| Hardness | ≤ 197 HB |

| Txheej txheem | EAF + LF + VOD + Forged + Kev kho cua sov (yeem) |

| SIZE RANGE | |

| Hloov | 10mm txog 360mm |

| NTAU NTAU | Dub, Peeled (K12), Txias Kos, Tig & Polished (H10, H11), Precision Av (H9, H8) |

Kev kho cua sov

| Kub ua haujlwm | 850-1150 oC |

| Case hardening | Ob chav hardeningoC |

| Carburising | 900-950 oC |

| Mos annealing | 650-700 oC |

| Nto hardening | 800-930 oC |

| Tempering | 150-210 oC |

| Ultrasonic kuaj | Raws li SEP 1921-84 |

Certificate of Quality: muab ua lus Askiv, ntxiv rau cov nqe lus ib txwm, cov txheej txheem tsim khoom, cov cuab yeej cuab tam (yield zog, tensile lub zog, elongation thiab hardness), forged piv, UT xeem, Grain loj, txoj kev kho cua sov thiab cov qauv ntawm yog muaj nyob rau ntawm Daim Ntawv Pov Thawj Zoo.

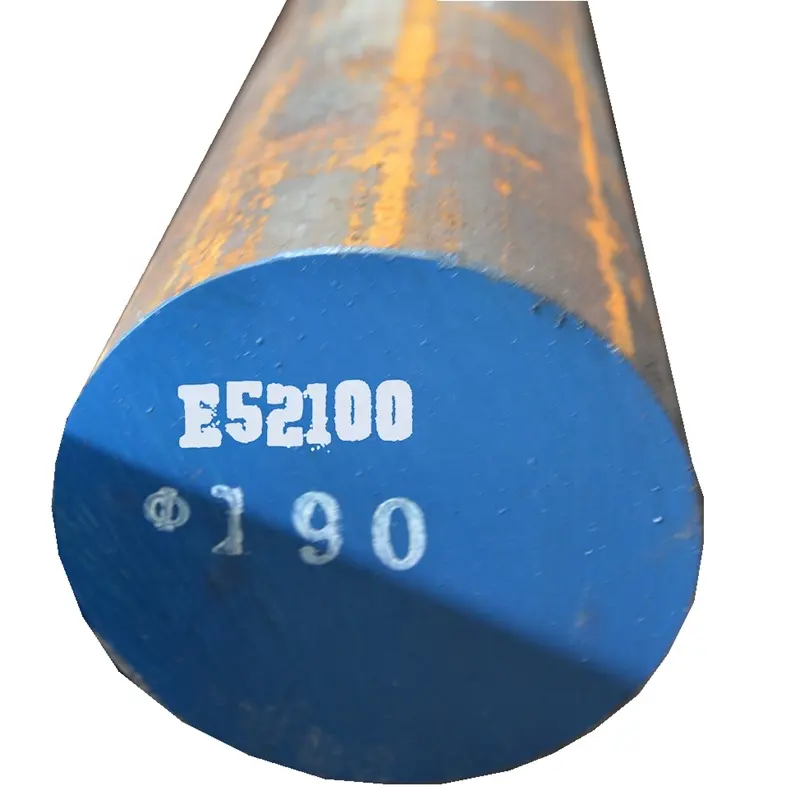

Kos npe: Thaum tshav kub kub tsis yog yuav txias stamped thiab Steel qib, txoj kab uas hla (mm), ntev (mm), thiab cov chaw tsim tshuaj paus LOGO thiab hnyav (kg) yog pleev xim rau.

Cov qauv sib npaug

| ASTM & AISI & SAE | JIS | EN DIN | EN IB | EN NF | ISO | GB |

| ib 86208 620h | SIB 220 | 1.6523 ib | 1.6523 ib | 1.6523 ib | ------ | 20CrNiMo |

SAE8620H Steel Bar Daim ntawv thov

Feem ntau siv rau kev tsim cov khoom tseem ceeb nrog lub zog siab thiab zoo plasticity, thiab rau kev tsim cov khoom tseem ceeb nrog kev ua haujlwm tshwj xeeb tom qab kho nitriding:

Heavy-duty arbors, bushings, Cam Followers, hnav pins, bearings, sprockets, gears thiab shafts, Clutch Dogs, Compressor Bolts, Extractors, Ntxuam Shafts, Hnyav Duty Gears, Pump Shafts, Sprockets, Tappets, Hnav Pins, Hlau Qhia thiab lwm yam. . Los yog siv tau rau kev siv siab tensile uncarburised tab sis los ntawm hardened thiab tempered.Nws yog siv dav los ntawm txhua qhov kev lag luam hauv kev lag luam rau cov khoom siv thiab cov shafts uas yuav tsum tau muaj qhov hnyav hnyav, lub zog tseem ceeb thiab cov khoom muaj zog.

Pob

1.By bundles, txhua nras hnyav nyob rau hauv 3 tons, rau me me txheejtxoj kab uas hla puag ncig bar, txhua pob nrog 4 - 8 steel strips.

2.20 feet thawv muaj qhov ntev, ntev hauv qab 6000mm

3.40 feet thawv muaj qhov ntev, ntev hauv qab 12000mm

4.By bulk nkoj, Freight nqi yog tsawg los ntawm bulk cargo, thiab lojhnyav qhov ntau thiab tsawg tsis tuaj yeem thauj mus rau hauv cov thawv tuaj yeem xa los ntawm cov khoom thauj ntau

Kev ruaj ntseg zoo

1. nruj raws li qhov yuav tsum tau ua

2. Qauv: Qauv muaj.

3. Kev sim: ntsev tsuag tshuaj ntsuam / Tensile xeem / Eddy tam sim no / Tshuaj muaj pes tsawg leeg kuaj raws li cov neeg siv khoom thov

4. Daim ntawv pov thawj: IATF16949, ISO9001, SGS thiab lwm yam.

5. EN 10204 3.1 Daim ntawv pov thawj