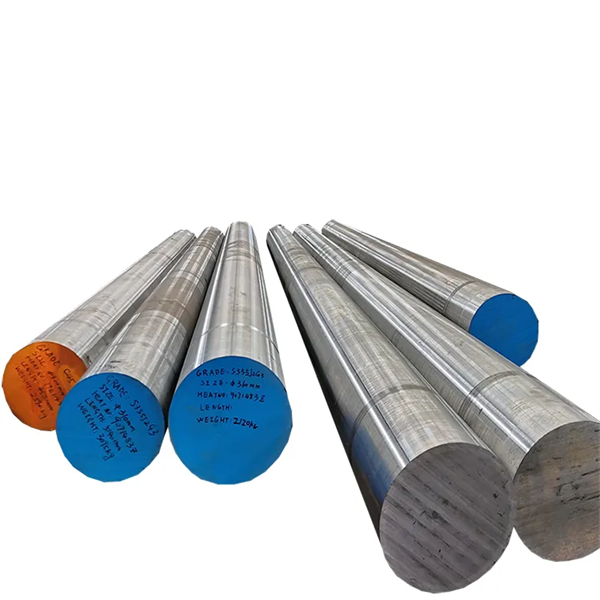

AISI 4130 SCM430 25crmo4 1.7218 Alloy Round Bar Engineering Steel

Specification

AISI 4130 steel tuav yog cov hlau tsis tshua muaj hlau.Lawv yog cov koom nrog Chrome-Molly alloy uas muaj chromium thiab molybdenum ua cov tshuaj ntxiv dag zog.AISI 4130 alloy steel yog nruab nrab carbon, qis alloy steel hauv ASTM A29 tus qauv.ASTM 4140 steel kuj yog feem ntau hu ua chromoly steel, los yog chrome moly steel, muaj nominally 0.28-0.33% Carbon, 0.8-1.1% Chromium thiab 0.15-0.25% Molybdenum.

AISI 4130 round steel bar muaj peev xwm ua haujlwm tau zoo, kev ua haujlwm tsawg tsawg, thiab kev qaug zog zoo heev.Nws belongs rau qeb ntawm nruab nrab mus rau siab harden peev xwm steel.Nrog rau kev kho cua sov kom zoo nws kuj tau yooj yim machined.Annealing ASTM 4130 alloy steel muaj ductility zoo heev.AISI 4130 steel feem ntau yog muab raws li puag ncig bar feem ntau nyob rau hauv lub hardened thiab tempered mob.

Tsis muaj

| Khoom npe | AISI 4130 SCM430 25crmo4 1.7218 Alloy Round Bar | |

| Khoom siv | ASTM | 4 130 |

| DIN | 25CrMo4/1.7218 | |

| GB | 30 CrMo | |

| Txuj | GB / T799, ASTM A29, A108, A321, A575, BS970, DIN1652, JIS G4051 | |

| OD | 6mm ibrau1200mm ib | |

| Nto | Dub pleev xim rau,Liab qab, Polished, Chrome Plated | |

| Specifications | Round bar | 8mm ~ 800 hli |

| Lub kaum sab xis | 3mm * 20mm * 20mm ~ 12mm * 800mm * 800mm | |

| Square bar | 4mm * 4mm ~ 100mm * 100mm | |

| Pav ca | 2 * 10mm ~ 100 * 500mm | |

| Hexagonal | 4mm ~ 800 hli | |

| Txheej txheem | Hluav taws xob rauv melted,forged thiab annealed, round bar tig. | |

| Hardness: | HBS 217 Max(Sib txawv ntawm tshav kubkev kho mob) | |

| UT Test | SEP 1921/84/2 C/c chav. | |

| Ua siab ntev | Dia -0/+ 0 ~ 5mm, Thickness -0/+ 0 ~ 5mm, Dav: -0/+ 0 ~ 10mm. | |

| Ntev | 2m, 4m, 5.8m, 6m, 11.8m, 12m lossis raws li xav tau. | |

| Pob | Seaworthy Ntim. | |

Equal Steel Qib

| Lub teb chaws | Askiv | Teb chaws USA | Nyiv | BS |

| Txuj | SIB 970 | ASTM A29 | JIS G4105 | TS EN 10083 |

| Qib | 708A25/708M25 | 4 130 | SWM 430 | 25CrMo4/1.7218 |

4130 steel chemical muaj pes tsawg leeg (%)

| Qib | C | Si | Mn | P | S | Cr | Mo | Ni |

| 4 130 | 0.28-0.33 Nws | 0.15-0.35 dr hab | 0.4-0.6 hli | 0.035 ib | 0.04 ib | 0.8-1.1 | 0.15-0.25 dr hab | / |

| 25 CrMo4 | 0.22-0.29 Nws | 0.4 | 0.6-0.9 hli | 0.025 ib | 0.035 ib | 0.9-1.2 hli | 0.15-0.30 Nws | / |

| SWM 430 | 0.28-0.33 Nws | 0.15-0.35 dr hab | 0.6-0.85 Nws | 0.03 ib | 0.03 ib | 0.9-1.2 hli | 0.15-0.30 Nws | / |

4130 steel mechanical zog thiab Daim Ntawv Thov

Cov khoom siv tshuab feem ntau suav nrog tensile lub zog, tawm lub zog, elongation, cheeb tsam lossis txo qis, hardness, cuam tshuam tus nqi, tsis yog xim hlau suav nrog thiab lwm yam. Kev kho cua sov sib txawv, cov khoom siv kho tshuab yuav txawv, xws li normalized, tempered, QT.

4 130steel baryog siv raucommercial aircraft, aircraft engine mounts, tub rog aircraft, tsheb, tshuab cuab yeej, hydraulic cov cuab yeej, pib sib tw, aerospace, roj thiab roj industries raws li forged valve lub cev thiab twj, ua liaj ua teb thiab tiv thaiv kev lag luam thiab lwm yam.

Quality Assurance

1.Strict raws li yuav tsum tau

2. Qauv: Qauv muaj.

3. Kev sim: ntsev tsuag tshuaj ntsuam / Tensile xeem / Eddy tam sim no / Tshuaj muaj pes tsawg leeg kuaj raws li cov neeg siv khoom thov

4.Certificate: IATF16949, ISO9001, SGS thiab lwm yam.

5. EN 10204 3.1 Daim ntawv pov thawj