STKM11A STKM14B steel raj rau lub tsheb

Specification

STKM11A yog qib steel rau carbon steel kav siv hauv cov khoom siv kho tshuab, tau los ntawm tus qauv JIS G3445, thiab yog qib Japanese.STKM11A steel yeeb nkab qib, cov khoom sib npaug rau SPHC, σ B ≥ 290MPa;Cov pa roj carbon steel rau STKM txhua yam qauv;

SPHC hom yog Ameslikas hom German thiab kuj tau siv nyob rau hauv Nyiv.Tom qab ntawd, nws tau qhia los ntawm lub tsev steel zeb Baosteel, sawv cev rau cov hlau kub dov (uas sib haum rau SPCC), sib npaug rau cov ntawv kub dov ntawm 10 # thiab 15 # steel hauv lub teb chaws tus qauv GB699 (National Standard for High Quality. Carbon Structural Steel), nrog rau cov ntsiab lus carbon ntawm ib ncig ntawm 0.1% -0.15%

Kev kho deg:

1. Bared

2.Black Painted (cov kua roj vanish txheej)

3. Galvanized

4. Yog '

5.Raws li cov neeg siv khoom.

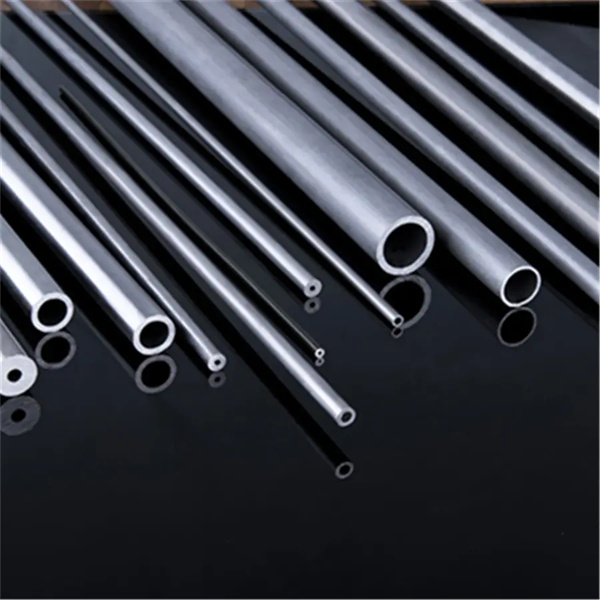

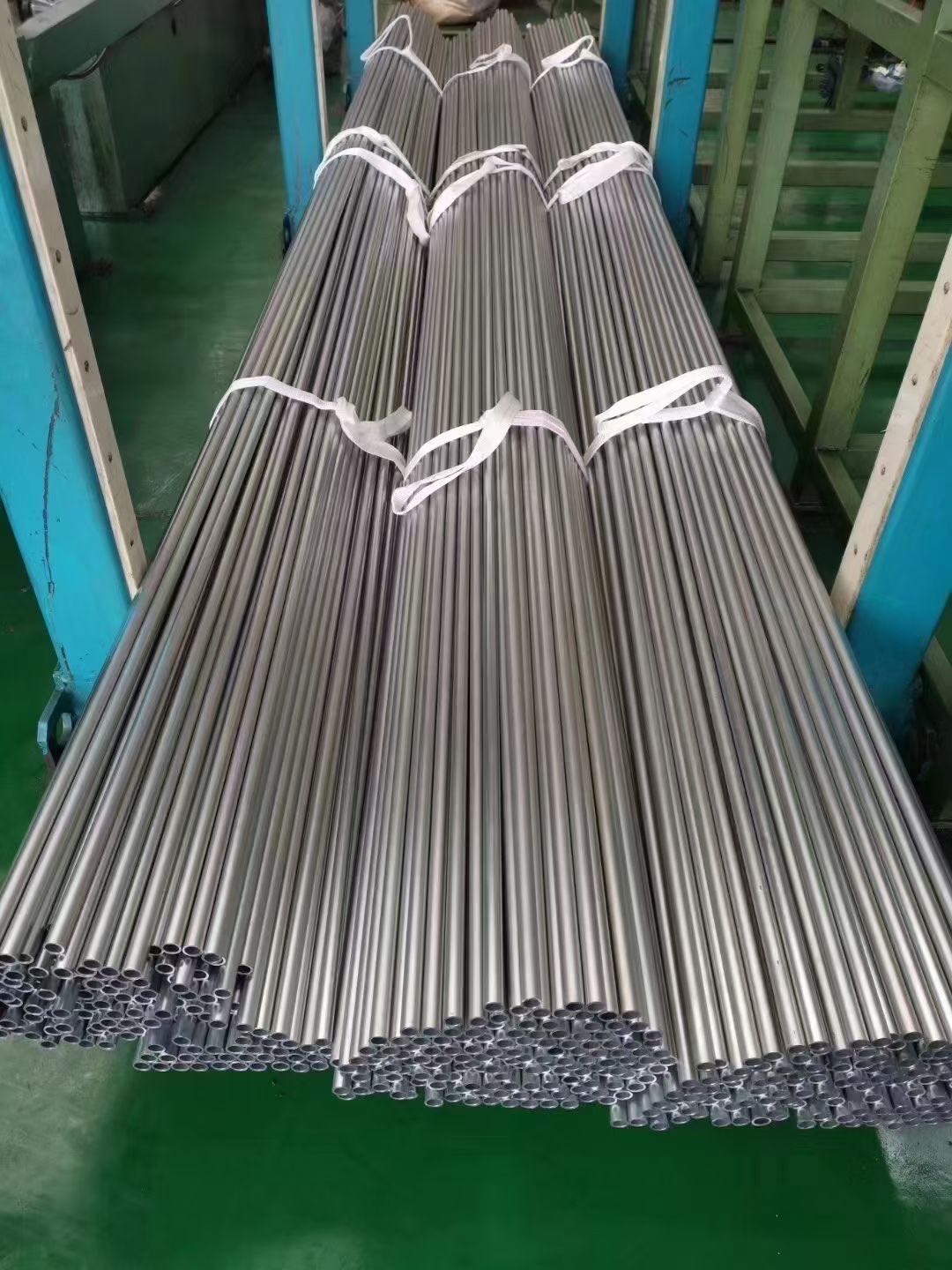

JIS STKM11A ~ 18C / DIN ST52 / ASTM A106, precision thiab nto roughness ntawm txias kos precision steel kav nrog puab thiab txheej diameters superior rau kub dov kav.Cov kev qhia tshwj xeeb tuaj yeem hloov kho kom tau raws li qhov xav tau siab dua rau lub zog tensile, lub zog tawm los, elongation, thiab lwm yam;Cold drawn precision steel kav nrog puab thiab sab nraud diameters yuav siv tau rau pneumatic thooj voos kheej kheej;Roj siab lub tog raj kheej;Motorcycle thiab tsheb kauj vab shock absorbable;Cua txias condenser;Locomotive pem hauv ntej diav rawg thiab rear diav rawg;Mechanical caj npab;Zaj duab xis recycling granular;Cov yeeb nkab;Lub raj mis tshuab tshuab;Leveling tshuab;Jack;Cultivator;Roller rau tshuab luam ntawv, thiab lwm yam.

JIS G3445 Precision steel hlab yog tsuas yog siv nyob rau hauv tsheb thiab precision machinery qhov chaw rau tsheb thiab lub tog raj kheej.kev siv siab, thiab tseem siv rau kev thauj cov chav, dej, cov kav dej.

Tshuaj muaj pes tsawg leeg

| Qib | Lub npe | Unit (%) | ||||||

| C | Si | Mn | P | S | Nb sau V | |||

| Qib 11 | A | STKM 11A | 0.12 max. | 0.35 max. | 0.60 max. | 0.040 max. | 0.040 max. | - |

| Qib 12 | A | STKM 12A | 0.20 max. | 0.35 max. | 0.6 max. | 0.04 max. | 0.04 max. |

|

| B | STKM 12B | |||||||

| C | STKM 12C | |||||||

| Qib 13 | A | STKM 13A | 0.25 max. | 0.35 max. | 0.30-0.90 Nws | 0.040 max. | 0.040 max. | - |

| B | STKM 13B | |||||||

| C | STKM 13C | |||||||

| Qib 14 | A | STKM 14A | 0.30 max. | 0.35 max. | 0.30-1.00 Nws | 0.040 max. | 0.040 max. | - |

| B | STKM 14B | |||||||

| C | STKM 14 C | |||||||

| Qib 15 | A | STKM 15A | 0.25-0.35 Nws | 0.35 max. | 0.30-1.00 Nws | 0.040 max. | 0.040 max. | - |

| C | STKM 15 C | |||||||

| Qib 16 | A | STKM 16A | 0.35-0.45 Nws | 0.40 max. | 0.40-1.00 Nws | 0.040 max. | 0.040 max. | - |

| C | STKM 16C | |||||||

| Qib 17 | A | STKM 17A | 0.45-0.55 Nws | 0.40 max. | 0.40-1.00 Nws | 0.040 max. | 0.040 max. | - |

| C | TSI 17C | |||||||

| Qib 18 | A | STKM 18A | 0.18 max. | 0.55 max. | 1.50 max. | 0.040 max. | 0.040 max. | - |

| B | STKM 18B | |||||||

| C | STKM 18C | |||||||

| Qib 19 | A | STKM 19A | 0.25 max. | 0.55 max. | 1.50 max. | 0.040 max. | 0.040 max. | - |

| C | STKM 19C | |||||||

| Qib 20 | A | STKM 20A | 0.25 max. | 0.55 max. | 1.60 max. | 0.040 max. | 0.040 max. | 0.15 max |

Mechanical Properties

| Qib Steel | Yield zog (Mpa) | Tensile zog (Mpa) | Elongation (%) | |

| Lub npe | Tsis muaj. | ReH (min) | Rm (min) | A(min) |

| STKM 11A |

| _ | 290 | 35 |

| STKM 12A |

| 175 | 340 | 35 |

| STKM 12B |

| 275 | 390 | 25 |

| STKM 12C |

| 355 | 4700 ib | 20 |

| STKM 13A |

| 215 | 370 | 30 |

| STKM 11B |

| 305 | 440 | 20 |

| STKM11C |

| 380 | 510 | 15 |

Ua siab ntev

| SIZE | Kev kam rau siab | Tshwj xeeb kam rau ua | ||

| OD | WT | OD | WT | |

| 4 hli-20mm | ± 0.25 hli | <3 hli ± 0.3 hli;

≥3mm ± 10%

| ± 0.05 hli | ± 0.05 hli |

| 20mm-30mm | ± 0.25 hli | ± 0.08 hli | ± 0.08 hli | |

| 31mm-40mm | ± 0.25 hli | ± 0.10 hli | ± 0.08 hli | |

| 41mm-49 hli | ± 0.25 hli | ± 0.15 hli | ± 0.15 hli | |

| 50mm-80mm | ± 0.5% | ± 0.20 hli | ± 0.20 hli | |

| 81mm-120mm | ± 0.5% | ± 0.30 hli | ± 0.30 hli | |

Kev ruaj ntseg zoo

1. nruj raws li JIS G3445 Standard los yog lwm yam qauv.

2. Qauv: Qauv yog pub dawb rau kev kuaj.

3. Kev sim: ntsev tsuag tshuaj ntsuam / Tensile xeem / Eddy tam sim no / Tshuaj muaj pes tsawg leeg kuaj raws li cov neeg siv khoom thov

4.Certificate: IATF16949, ISO9001, SGS thiab lwm yam.

5.EN 10204 3.1 Ntawv pov thawj

Ntxiv dag zog rau kev tshuaj xyuas cov khoom nyob rau hauv txhua theem ntawm kev tsim khoom, nruab nrog cov khoom siv ua tiav: kev ntsuas tsis muaj kev puas tsuaj tam sim no, kev kub siab tiv thaiv kev sim tshuab, universal mechanical tensile testing machine, bending flattening flares testing machine, cleanliness analyzer, metal element analyzer, etc. Ua tau raws li cov khoom siv kho tshuab ntawm cov khoom, cov txheej txheem kev ntsuas kev ua tau zoo, muab lub zog lav rau cov khoom tsim nyog.