Steel Tube rau tsheb qhov chaw / SCM420H SCM440H SCM435 tsheb steel hlab

Nta

Khoom Qib:

STKM 11A 12A 12B 12C 13A 13B 13C 14A 14B 14C 15A 15C thiab lwm yam.

Kev kho deg:

1. Bared

2.Black Painted (cov kua roj vanish txheej)

3. Galvanized

4. Yog '

5.Raws li cov neeg siv khoom.

JIS G3445 Precision steel hlab yog tsuas yog siv nyob rau hauv tsheb thiab precision machinery qhov chaw rau tsheb thiab lub tog raj kheej.kev siv siab, thiab tseem siv rau kev thauj cov chav, dej, cov kav dej.

Tshuaj muaj pes tsawg leeg

| Qib | Lub npe | Unit (%) | ||||||

| C | Si | Mn | P | S | Nb sau V | |||

| Qib 11 | A | STKM 11A | 0.12 max. | 0.35 max. | 0.60 max. | 0.040 max. | 0.040 max. | - |

| Qib 12 | A | STKM 12A | 0.20 max. | 0.35 max. | 0.6 max. | 0.04 max. | 0.04 max. | |

| B | STKM 12B | |||||||

| C | STKM 12C | |||||||

| Qib 13 | A | STKM 13A | 0.25 max. | 0.35 max. | 0.30-0.90 Nws | 0.040 max. | 0.040 max. | - |

| B | STKM 13B | |||||||

| C | STKM 13C | |||||||

| Qib 14 | A | STKM 14A | 0.30 max. | 0.35 max. | 0.30-1.00 Nws | 0.040 max. | 0.040 max. | - |

| B | STKM 14B | |||||||

| C | STKM 14 C | |||||||

| Qib 15 | A | STKM 15A | 0.25-0.35 Nws | 0.35 max. | 0.30-1.00 Nws | 0.040 max. | 0.040 max. | - |

| C | STKM 15 C | |||||||

| Qib 16 | A | STKM 16A | 0.35-0.45 Nws | 0.40 max. | 0.40-1.00 Nws | 0.040 max. | 0.040 max. | - |

| C | STKM 16C | |||||||

| Qib 17 | A | STKM 17A | 0.45-0.55 Nws | 0.40 max. | 0.40-1.00 Nws | 0.040 max. | 0.040 max. | - |

| C | TSI 17C | |||||||

| Qib 18 | A | STKM 18A | 0.18 max. | 0.55 max. | 1.50 max. | 0.040 max. | 0.040 max. | - |

| B | STKM 18B | |||||||

| C | STKM 18C | |||||||

| Qib 19 | A | STKM 19A | 0.25 max. | 0.55 max. | 1.50 max. | 0.040 max. | 0.040 max. | - |

| C | STKM 19C | |||||||

| Qib 20 | A | STKM 20A | 0.25 max. | 0.55 max. | 1.60 max. | 0.040 max. | 0.040 max. | 0.15 max |

Mechanical zog

| Qib Steel | Yield zog (Mpa) | Tensile zog (Mpa) | Elongation (%) | |

| Lub npe | Tsis muaj. | ReH (min) | Rm (min) | A(min) |

| STKM 11A |

| _ | 290 | 35 |

| STKM 12A |

| 175 | 340 | 35 |

| STKM 12B |

| 275 | 390 | 25 |

| STKM 12C |

| 355 | 4700 ib | 20 |

| STKM 13A |

| 215 | 370 | 30 |

| STKM 11B |

| 305 | 440 | 20 |

| STKM11C |

| 380 | 510 | 15 |

Ua siab ntev

| SIZE | Kev kam rau siab | Tshwj xeeb kam rau ua | ||

| OD | WT | OD | WT | |

| 4 hli-20mm | ± 0.25 hli | <3 hli± 0.3 hli;

≥3mm ± 10%

| ± 0.05 hli | ± 0.05 hli |

| 20mm-30mm | ± 0.25 hli | ± 0.08 hli | ± 0.08 hli | |

| 31mm-40mm | ± 0.25 hli | ± 0.10 hli | ± 0.08 hli | |

| 41mm-49 hli | ± 0.25 hli | ± 0.15 hli | ± 0.15 hli | |

| 50mm-80mm | ± 0.5% | ± 0.20 hli | ± 0.20 hli | |

| 81mm-120mm | ± 0.5% | ± 0.30 hli | ± 0.30 hli | |

Kev xa khoom

| Lub npe | Cim | Kev piav qhia |

| Txias tiav (nyuaj) | BK (+C) | Cov raj tsis tau txais kev kho cua sov tom qab qhov kawg txias txias thiab, yog li, muaj kev tiv thaiv siab heev rau deformation. |

| Cold tiav (Soft) | BKW | Kev kho cua sov zaum kawg yog ua raws li kev kos duab txias uas muaj kev txwv tsis pub deformation.Kev tsim nyog ntxiv tso cai rau qee qhov kev ua kom txias (xws li khoov, nthuav dav) |

| (+ LC) | ||

| Txias tiav thiab kev ntxhov siab | BKS(+SR) | Kev kho cua sov yog siv tom qab lub caij txias kawg.Raws li cov txheej txheem tsim nyog, qhov nce ntawm cov kev ntxhov siab uas cuam tshuam cuam tshuam ua rau ob qho tib si tsim thiab machining mus rau ib qho twg. |

| Annealed | GBK (+A) | Cov txheej txheem txias txias kawg yog ua raws li kev sib tsoo hauv qhov chaw tswj tau. |

| Li qub | NBK (+ N) | Cov txheej txheem txias txias kawg yog ua raws li los ntawm annealing saum toj kawg nkaus transformation point nyob rau hauv ib qho chaw tswj. |

Kev xa khoom

| Lub npe | Cim | Kev piav qhia |

| Txias tiav (nyuaj) | BK (+C) | Cov raj tsis tau txais kev kho cua sov tom qab qhov kawg txias txias thiab, yog li, muaj kev tiv thaiv siab heev rau deformation. |

| Cold tiav (Soft) | BKW | Kev kho cua sov zaum kawg yog ua raws li kev kos duab txias uas muaj kev txwv tsis pub deformation.Kev tsim nyog ntxiv tso cai rau qee qhov kev ua kom txias (xws li khoov, nthuav dav) |

| (+ LC) | ||

| Txias tiav thiab kev ntxhov siab | BKS(+SR) | Kev kho cua sov yog siv tom qab lub caij txias kawg.Raws li cov txheej txheem tsim nyog, qhov nce ntawm cov kev ntxhov siab uas cuam tshuam cuam tshuam ua rau ob qho tib si tsim thiab machining mus rau ib qho twg. |

| Annealed | GBK (+A) | Cov txheej txheem txias txias kawg yog ua raws li kev sib tsoo hauv qhov chaw tswj tau. |

| Li qub | NBK (+ N) | Cov txheej txheem txias txias kawg yog ua raws li los ntawm annealing saum toj kawg nkaus transformation point nyob rau hauv ib qho chaw tswj. |

| High Precision Steel Tubes hauv Tshuag | ||||||||||

| OD | Thickness (hli) | |||||||||

| mm | ||||||||||

| 4 | 4 * 1 | |||||||||

| 6 | 6 * 1 | 6 * 1.5 hli | 6 * 2 | |||||||

| 8 | 8 * 1 | 8 * 1.5 hli | 8 * 2 | |||||||

| 10 | 10 * 1 | 10 * 1.5 hli | 10 * 2 | 10 * 2.5 hli | ||||||

| 12 | 12 * 1 | 12 * 1.5 hli | 12 * 2 | 12 * 2.5 hli | 12 * 3 | |||||

| 14 | 14 * 1 | 14 * 1.5 hli | 14 * 2 | 14 * 2.5 hli | 14 * 3 | |||||

| 15 | 15 * 1 | 15 * 1.5 hli | 15 * 2 | 15 * 2.5 hli | 15 * 3 | 15 * 3.5 hli | ||||

| 16 | 16 * 1 | 16 * 1.5 hli | 16 * 2 | 16 * 2.5 hli | 16 * 3 | 16 * 3.5 hli | 16 * 4 | 16 * 4.5 hli | ||

| 18 | 18 * 1 | 18 * 1.5 hli | 18 * 2 | 18 * 2.5 hli | 18 * 3 | 18 * 3.5 hli | 18 * 4 | 18 * 4.5 hli | ||

| 20 | 20 * 1 | 20 * 1.5 hli | 20 * 2 | 20 * 2.5 hli | 20 * 3 | 20 * 3.5 hli | 20 * 4 | 20 * 4.5 hli | 20 * 5 | |

| 22 | 22 * 1 | 22 * 1.5 hli | 22 * 2 | 22 * 2.5 hli | 22 * 3 | 22 * 3.5 hli | 22 * 4 | 22 * 4.5 hli | 22 * 5 | |

| 25 | 25 * 1 | 25 * 1.5 hli | 25 * 2 | 25 * 2.5 hli | 25 * 3 | 25 * 3.5 hli | 25 * 4 | 25 * 4.5 hli | 25 * 5 | |

| 28 | 28 * 1 | 28 * 1.5 hli | 28 * 2 | 28 * 2.5 hli | 28 * 3 | 28 * 3.5 hli | 28 * 4 | 28 * 4.5 hli | 28 * 5 | |

| 30 | 30 * 1 | 30 * 1.5 hli | 30 * 2 | 30 * 2.5 hli | 30 * 3 | 30 * 3.5 hli | 30 * 4 | 30 * 4.5 hli | 30 * 5 | 30 * 6 |

| 32 | 32 * 1.5 hli | 32 * 2 | 32 * 2.5 hli | 32 * 3 | 32 * 3.5 hli | 32 * 4 | 32 * 4.5 hli | 32 * 5 | 32 * 6 | |

| 34 | 34 * 1.5 hli | 34 * 2 | 34 * 2.5 hli | 34 * 3 | 34 * 3.5 | 34 * 4 | 34 * 4.5 | 34 * 5 | 34 * 6 | |

| 35 | 35 * 1.5 hli | 35 * 2 | 35 * 2.5 hli | 35 * 3 | 35 * 3.5 hli | 35 * 4 | 35 * 4.5 hli | 35 * 5 | 35 * 6 | |

| 38 | 38 * 2 | 38 * 2.5 hli | 38 * 3 | 38 * 3.5 hli | 38 * 4 | 38 * 4.5 hli | 38 * 5 | 38 * 6 | ||

| 40 | 40 * 2 | 40 * 2.5 hli | 40 * 3 | 40 * 3.5 hli | 40 * 4 | 40 * 4.5 hli | 40 * 5 | 40 * 6 | ||

| 42 | 42 * 2 | 42 * 2.5 hli | 42 * 3 | 42 * 3.5 hli | 42 * 4 | 42 * 4.5 hli | 42 * 5 | 42 * 6 | ||

| 45 | 45 * 2 | 45 * 2.5 hli | 45 * 3 | 45 * 3.5 hli | 45 * 4 | 45 * 4.5 hli | 45 * 5 | 45 * 6 | ||

| 46 | 46 * 2 | 46 * 2.5 hli | 46 * 3 | 46 * 3.5 hli | 46 * 4 | 46 * 4.5 hli | 46 * 5 | 46 * 6 | ||

| 48 | 48 * 2 | 48 * 2.5 hli | 48 * 3 | 48 * 3.5 hli | 48 * 4 | 48 * 4.5 hli | 48 * 5 | 48 * 6 | ||

| 50 | 50 * 2 | 50 * 2.5 hli | 50 * 3 | 50 * 3.5 hli | 50 * 4 | 50 * 4.5 hli | 50 * 5 | 50 * 6 | ||

| 54 | 54 * 2.5 hli | 54 * 3 | 54 * 3.5 hli | 54 * 4 | 54 * 4.5 hli | 54 * 5 | 54 * 6 | |||

| 60 | 60 * 2.5 hli | 60 * 3 | 60 * 3.5 hli | 60 * 4 | 60 * 4.5 hli | 60 * 5 | 60 * 6 | |||

| 65 | 65 * 3 | 65 * 3.5 hli | 65 * 4 | 65 * 4.5 hli | 65 * 5 | 65 * 6 | ||||

| 75 | 75 * 3.5 hli | 75 * 4 | 75 * 4.5 hli | 75 * 5 | 75 * 6 | |||||

| 76 | 76 * 4 | 76 * 4.5 hli | 76 * 5 | 76 * 6 | ||||||

| 89 | 89 * 6 | |||||||||

| Nco tseg: Peb tuaj yeem tsim lwm qhov ntau thiab tsawg raws li koj xav tau.Kev kho deg: ci, Galvanized, Phosphate thiab lwm yam. | ||||||||||

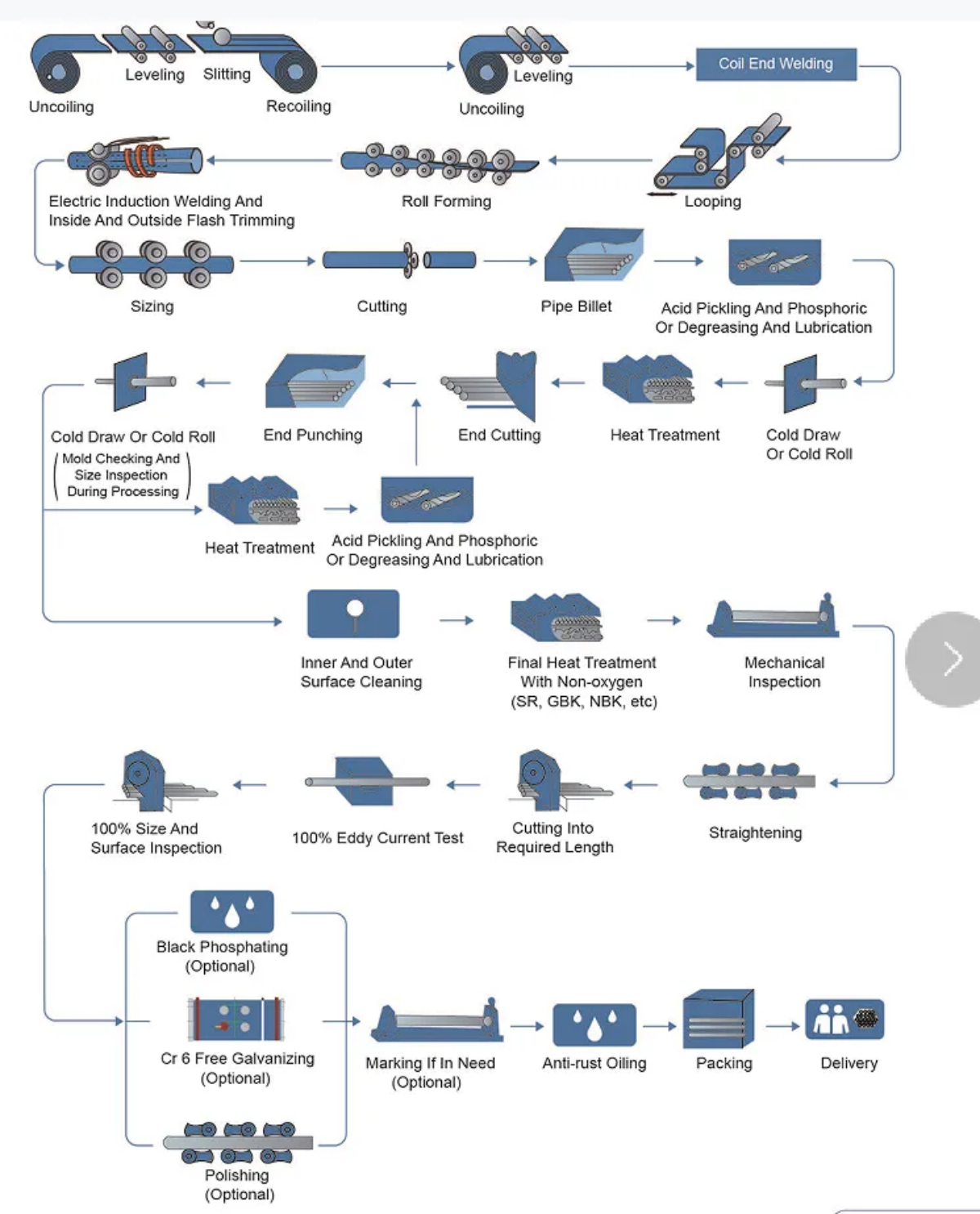

Txheej txheem tsim khoom

Qhov zoo

Ntxiv dag zog rau kev tshuaj xyuas cov khoom nyob rau hauv txhua theem ntawm kev tsim khoom, nruab nrog cov khoom siv ua tiav: kev ntsuas tsis muaj kev puas tsuaj tam sim no, kev kub siab tiv thaiv kev sim tshuab, universal mechanical tensile testing machine, bending flattening flares testing machine, cleanliness analyzer, metal element analyzer, etc. Ua tau raws li cov khoom siv kho tshuab ntawm cov khoom, cov txheej txheem kev ntsuas kev ua tau zoo, muab lub zog lav rau cov khoom tsim nyog.

Kev ruaj ntseg zoo

1. nruj raws li JIS G3445 Standard los yog lwm yam qauv.

2. Qauv: Qauv yog pub dawb rau kev kuaj.

3. Kev sim: ntsev tsuag tshuaj ntsuam / Tensile xeem / Eddy tam sim no / Tshuaj muaj pes tsawg leeg kuaj raws li cov neeg siv khoom thov

4.Certificate: IATF16949, ISO9001, SGS thiab lwm yam.

5.EN 10204 3.1 Ntawv pov thawj