ISO Non metallic Inclusion Inspection Standards:

(1) ISO 4967: 2013

TS EN ISO 4967: 2013 "Kev txiav txim siab ntawm cov ntsiab lus tsis yog xim hlau suav nrog hauv cov hlau - Cov Qauv Ntsuas Ntsuas Kab Ntsuas Kev Ntsuas Ntsuas" hloov ISO 4967-1998, tab sis nws cov ntsiab lus tsuas muaj kev hloov pauv tsawg, thiab nws txoj kev tshuaj xyuas thiab daim ntawv ntsuas ntsuas tsis tau hloov pauv.Lub xyoo 1988 ntawm tus qauv no tau sib npaug los ntawm GB / T 10561-2005.

(2) ISO 9341-1996

ISO 9341-1996 "Cov Khoom Siv Khoos thiab Kev Txiav Txim Siab Rau Cov Txheej Txheem Tsis Txaus Ntseeg thiab cov kauj ruam rau kev nthuav dav siv cov ntsiab muag tsis sib xws.TS EN ISO 18369.3: 2006 Cov khoom siv kho qhov muag thiab kho qhov muag - Kev tiv thaiv lo ntsiab muag - Ntu 3: Kev sim cov txheej txheem

American non-metallic inclusion soj ntsuam qauv:

(1) ASTM B796-2014

ASTM B796-2014 "Test Method for Non-metallic Inclusion Content in Powder Forged Parts", hloov ASTM B796-2007, tsim nyog rau kev txiav txim siab metallographic ntawm cov qib tsis yog xim hlau suav nrog hauv cov hmoov forged qhov chaw, xav tau 100% porosity nrhiav pom hauv cheeb tsam tseem ceeb ntawm tus qauv.Yog tias muaj qhov khoob, nws yog qhov nyuaj rau kev paub qhov txawv ntawm qhov pores los ntawm oxide inclusions.

(2) ASTM E45-2013

ASTM E45-2013 "Kev Ntsuas Method rau Kev Txiav Txim Cov Ntsiab Lus Hauv Cov Hlau" yog cov qauv siv dav siv tsis yog hlau suav nrog cov qauv tshuaj ntsuam xyuas, uas suav nrog plaub txoj kev tshuaj xyuas macroscopic thiab tsib txoj hauv kev tshuaj xyuas microscopic (kev qhia phau ntawv thiab cov duab tsom) los piav qhia cov ntsiab lus ntawm kev suav nrog hauv cov hlau. thiab tshaj tawm txoj kev soj ntsuam xyuas.tsib txoj kev tshuaj xyuas microscopic muaj xws li: A txoj kev (qhov phem tshaj plaws ntawm txoj kev saib), B txoj kev (ntev txoj kev), C txoj kev (oxide thiab silicate method) D txoj kev (tsawg inclusion cov ntsiab lus txoj kev) thiab E txoj kev (SAM rating method);ASTM E45 tau tsim ntau cov qauv siv daim ntawv qhia (JK maps thiab SAE maps) los piav txog cov yam ntxwv (qhov loj me, hom, thiab ntau) ntawm cov kev suav nrog.Daim ntawv qhia SAE tuaj yeem pom hauv J422 cov txheej txheem kev ua haujlwm pom zoo hauv SAE phau ntawv;Qhov spectra ntawm Txoj Kev A (qhov phem tshaj plaws ntawm kev pom), Txoj Kev D (cov ntsiab lus tsis tshua muaj), thiab Txoj Kev E (SAM rating) tau tsim los ntawm JK spectra, thaum Txoj Kev C (Oxide thiab silicate method) siv SAE spectra.

(3) ASTM E1122-1996

ASTM E1122-1996 "Standard Test Method for Determining JK Inclusion Level by Automatic Image Analysis" tau txiav tawm xyoo 2006 thiab tau muab tso rau hauv ASTM E45-2013 tshiab, Txoj Kev A thiab D.

(4) ASTM E1245-2003 (2008)

ASTM E1245-2003 (2008) "Txoj Kev Xeem Txuj Ci rau Kev Txiav Txim ntawm Kev Sib Txuas lossis Qib Thib Ob Cov Txheej Txheem Cov ntsiab lus hauv cov hlau los ntawm Kev Tshawb Fawb Cov Duab."Haum rau kev siv cov duab tsis siv neeg los ntsuas cov ntsiab lus ntawm endogenous inclusions thiab theem ob microstructure hauv hlau.Vim tias qhov sib txawv thiab tsis paub txog kev faib tawm ntawm exogenous inclusions, tus qauv no tsis muaj feem xyuam rau kev ntsuas exogenous inclusions nyob rau hauv steel los yog lwm yam hlau.

(5) ASTM E2142-2008

ASTM E2142-2008 "Test Method for Evaluation and Classification of Inclusions in Steel by Scanning Electron Microscopy".Raws li cov txheej txheem teev tseg hauv ASTM E45 thiab ASTM E1245, qhov kev ntsuas ntau ntawm cov ntsiab lus suav nrog hauv cov hlau yog ua los ntawm kev siv lub tshuab ntsuas hluav taws xob scanning;Kev txiav txim siab ntawm qhov ntau, qhov loj me, thiab kev faib morphology ntawm kev suav nrog yog cais raws li cov txheej txheem tshuaj.

(6) ASTM E2283-2008 (2014)

Raws li paub zoo, qhov tsis ua haujlwm ntawm cov khoom siv kho tshuab xws li lub zog thiab cov kabmob feem ntau tshwm sim los ntawm qhov muaj ntau ntawm cov hlau tsis muaj hlau oxide suav nrog.Kev soj ntsuam microscopic ntawm cov khoom ua tsis tau zoo feem ntau taug qab qhov pom ntawm kev suav nrog.Kev kwv yees ntawm lub neej qaug zog ntawm cov khoom ua tsis tau zoo tsis tuaj yeem ntsuas qhov tsim nyog los ntawm kev soj ntsuam cov qauv xws li ASTM E45, ASTM E1122, thiab ASTM E1245.ASTM E2283-2008 (2014) "Code for Analysis of Extreme Values of Non metallic Inclusions and Other Microstructure Characteristics in Steel" tau tshwm sim nyob rau hauv cov xwm txheej no.Cov txheej txheem no tsim ib txoj hauv kev uas siv cov txiaj ntsig zoo tshaj plaws, uas muaj feem cuam tshuam rau lub neej ntawm cov khoom siv thiab kev faib tawm loj.Zoo li ASTM E1245-2003 (2008), tus qauv no tsis muaj feem xyuam rau kev soj ntsuam ntawm exogenous inclusions nyob rau hauv steel thiab lwm yam hlau.

German non-metallic inclusion soj ntsuam qauv:

(1) DIN 50602-1985

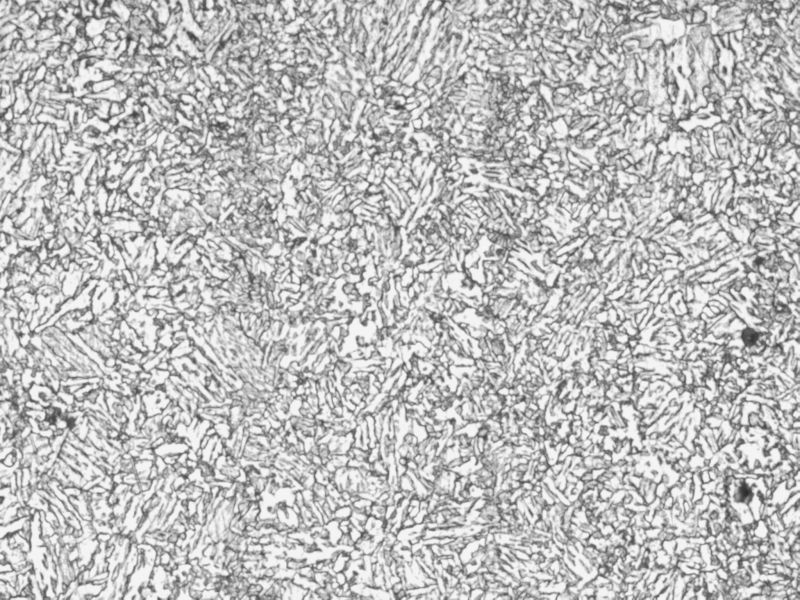

DIN 50602-1985 "Kev soj ntsuam Microscopic rau kev ntsuas cov ntsiab lus tsis yog xim hlau hauv cov hlau zoo siv cov duab kos duab" yog dav siv los ua cov qauv tshuaj ntsuam xyuas microscopic tus qauv rau cov ntsiab lus tsis yog xim hlau suav nrog hauv cov hlau zoo, siv los ntawm ntau dua 120 cov qauv khoom.Cov qauv no faib cov non-metallic inclusions nyob rau hauv steel rau plaub pawg: SS hom, OA hom, OS hom, thiab OG hom, sib xws rau sulfide inclusions, oxide inclusions, silicate inclusions, thiab kheej kheej oxide inclusions, raws li.Cov 4 hom kev suav nrog no tau muab faib ua 9 qib, sawv cev los ntawm 0-8.Cov qib uas nyob ib sab ua rau qhov sib txawv ntawm ob zaug ntawm qhov chaw suav nrog.Qhov ntsuas qhov ntau yog ib lub cub tawg lossis ib pawg ntawm cov khoom, thiab feem ntau tsis muaj tsawg dua 6 cov qauv.Peb daim duab yog siv los ntsuas cov qib ntawm kev suav nrog.Nyob rau tib theem, sulfide inclusions (SS hom) thiab spherical oxide inclusions (OG hom) muab faib ua ob series raws li qhov sib txawv ntawm inclusion width thiab thickness, hos oxide inclusions (OA type) thiab silicate inclusions (OS type) muab faib ua peb series.Nyob rau hauv txhua hom kev suav nrog thiab txhua series, sib txuas qhov ntev ntawm kev suav nrog yog muab, thiab ib lub rooj ntawm qhov ntev sib xws rau kev suav nrog ntawm qhov dav sib txawv kuj tau muab.Muaj ob txoj kev ntsuam xyuas rau DIN 50602-1985: M txoj kev thiab K txoj kev.M-txoj kev yog sau cov qib siab tshaj plaws ntawm kev suav nrog rau tag nrho thaj chaw kuaj xyuas, thiab tom qab sib cais ntsuas thiab sau ntau yam kev suav nrog hauv cov qauv xaiv, suav cov lej lej.K-txoj kev suav suav suav nrog los ntawm ib qib uas tau teev tseg, yog li tus qauv tshwj xeeb siv rau cov hlau tshwj xeeb.Yog li ntawd, qhov qis tshaj ntawm kev ntsuam xyuas nyob ntawm cov txheej txheem steel smelting, siv cov khoom siv, thiab cov khoom loj.Tus lej tom qab K yog qhov tsawg kawg nkaus ntawm cov qib uas siv hauv kev ntsuam xyuas siv daim duab.Piv txwv li, K4 yog hais txog qhov zaus ntawm qhov tshwm sim ntawm kev suav nrog qib pib ntawm qib 4. Cov qib ntawm kev suav nrog nws txawv, thiab lawv cov coefficients txaus ntshai kuj txawv.Kev muab ntau zaus los ntawm cov coefficient yields tag nrho cov kev suav nrog hauv ib qho qauv.Tag nrho cov naj npawb ntawm kev suav nrog hauv tag nrho cov qauv hauv pawg qauv raug ntxiv, thiab cov txiaj ntsig tau hloov mus rau 1000 mm2, uas yog tag nrho qhov ntsuas ntawm kev suav.K4 feem ntau siv, thiab thaum xam, OS hom inclusions feem ntau muab faib ua OA.Tam sim no, tus qauv no tau raug siv tsis raug thiab tsis muaj kev hloov kho tshiab los hloov nws.Nws pawg kws tshaj lij pom zoo siv DIN EN 10247-2007 rau kev tshuaj xyuas cov ntsiab lus tsis yog xim hlau suav nrog hauv cov hlau.

(2) DIN EN 10247-2007

TS EN 10247-2007 Kev kuaj xyuas microscopic ntawm cov ntsiab lus tsis yog xim hlau suav nrog hauv cov hlau uas siv cov duab qauv " ntawm non-metallic inclusion cov ntsiab lus nyob rau hauv steel siv cov qauv duab ".Cov txheej txheem no faib cov non-metallic inclusions nyob rau hauv steel rau hauv 6 hom yooj yim, sawv cev los ntawm EA, EB, EC, ED, EF, thiab AD, Cov kev ntsuam xyuas tau muab faib ua P txoj kev (worst inclusion method), M method (qhov phem tshaj plaws ntawm saib txoj kev), thiab K txoj kev (qhov nruab nrab ntawm qhov kev pom txoj kev), uas M txoj kev thiab K txoj kev yog raws li DIN 50602

Cov lus piav qhia hauv xyoo 1985 yog qhov ua tau zoo, thiab ntau cov qauv tsim khoom tshiab hauv Tebchaws Europe tau pib siv tus qauv no.

(3) Lwm yam

Cov qauv ntsuas ntsuas cuam tshuam nrog kev tshuaj xyuas cov khoom tsis yog xim hlau kuj suav nrog: SEP 1570-1971 "Microscopic Inspection Method for Non-metallic Inclusion Content Rating Charts of Special Steel", SEP 1570-1971 (Ntxiv) "Kev Tshuaj Ntsuam Xyuas Microscopic rau Nonmetallic Cov ntsiab lus ntsuas kab ntawv ntawm Fine thiab Ntev Tshwj Xeeb Hlau ", thiab SEP 1572-1971 "Kev Tshuaj Ntsuam Xyuas Microscopic rau Sulfide Cov Ntsiab Lus Ntsuas Cov Kab Ntawv Dawb Txiav Hlau"

Kev soj ntsuam cov qauv rau non-metallic inclusions nyob rau hauv lwm lub teb chaws:

JIS G 0555: 2003 "Microscopic test method for non-metallic inclusions in steel" (Japanese standard).

Nws yog ib txoj hauv kev kuaj microscopic rau kev txiav txim siab uas tsis yog-hlau suav nrog hauv cov khoom dov lossis forged steel (nrog rau qhov sib piv ntawm tsawg kawg 3).Cov txheej txheem tshuaj xyuas tiag tiag rau kev suav nrog hauv tus qauv no tau muab faib ua hom A, B txoj kev, thiab taw tes suav nrog kev tshuaj xyuas microscopic.Txoj kev A thiab B txoj kev ua tau zoo ib yam nrog cov qauv kev sawv cev hauv ISO 4967: 2013, thiab cov ntsiab lus xam cov qauv sawv cev rau cov purity ntawm cov hlau los ntawm feem pua ntawm cov cheeb tsam nyob hauv kev suav nrog.Cov qauv no tau siv dav los ntsuas qhov tsim nyog ntawm cov hlau rau daim ntawv thov, tab sis vim yog lub ntsiab lus ntawm cov neeg sim, nws nyuaj rau kev ua tiav cov txiaj ntsig zoo, yog li muaj ntau cov qauv thiab kev kwv yees xav tau rau daim ntawv thov.

TS EN 7926-1998 (R2014) "Quantitative micrographic method rau kev txiav txim siab feem pua cov ntsiab lus ntawm cov khoom tsis yog xim hlau hauv cov hlau" (British qauv),

Ob txoj kev yees duab microscopic rau kev txiav txim siab cov ntsiab lus ntawm cov khoom tsis yog xim hlau hauv cov cam khwb cia hlau tau piav qhia meej.Cov cheeb tsam feem ntawm cov tsis yog xim hlau suav nrog hauv cov qauv cam khwb cia hlau tau teev tseg, thiab feem pua ntawm cov khoom tsis yog xim hlau suav nrog hauv plaub txoj kev melting thiab refining siv los ntawm steel foundries kuj tau teev tseg.

Tshiab Gapower Hlauyog tus kws tshaj lij dawb txiav steel chaw tsim khoom.Cov khoom tseem ceeb suav nrog 1212 1213 1214 1215 1140 1144 12l13 12l14,12l15 11SMn30 thiab lwm yam. Cov neeg siv khoom tuaj yeem nrhiav txhua hom raj uas lawv xav tau.

Post lub sij hawm: Dec-25-2023